Leaderboard

Popular Content

Showing content with the highest reputation on 10/28/2021 in all areas

-

4 points

-

Ford just slammed thru $17 price point and is up over 8% in last day or so. Nice pop. Analyst on CNBC is giving an $80/share target price. Don't know about that, but $20 price target certainly is in sight short term. I would say keep the dividend yield under 3% and let the stock price fly. Stocks with high dividend yield don't do well in this economy.3 points

-

Bob - the frustrating part is this has been posted and discussed at least 4 or 5 times (maybe a lot more) over the last few months. In this case a search for COVP would have shown that.3 points

-

Is it just me or do you feel almost dirty after dealing with these guys? SiriusXm has to have the worst customer service going. Slimy, shady business practices. Almost like dealing with an old time shady car dealer.2 points

-

That is not always true. Ford chose to fund its future investments by redirecting existing resources and cancelling less profitable projects and vehicles. There is a limit to how much a company can invest without overextending fixed overhead and debt. Ford obviously believes it can do both.2 points

-

WOW and very nice ? and I think this has removed any question…. I know it takes time for you to do want you do and it is very much appreciated. Thank you ice-capades2 points

-

2021 Ford Customer Order Verification for Priority Scheduling and Allocation (Revised 06/09/2021) WHAT IS HAPPENING • The Customer Order Verification Program (COVP) will be opening to all unscheduled orders on all vehicle lines (excluding Mach-E, Bronco and specialty units) • Verified orders will receive priority scheduling and will receive incremental allocation • The required documentation for COVP approval will again require a signed and dated buyers order along with a copy of the customer’s driver’s license. A WBDO Screenshot or DORA is no longer adequate documentation for approval. • Any previously approved retails will not have to be resubmitted SUMMARY Dealers will be able to utilize the existing COVP website on https:// to register retail orders for all vehicle lines (excluding Mach-E, Bronco and specialty units). Verified orders will receive priority scheduling and will receive incremental allocation. Vehicles that are not verified will still be scheduled but will be scheduled within the dealer’s regularly earned allocation. Note that while this program utilizes the same process as the Retail Order Incentive, only previously communicated vehicle lines are eligible for the incentive. Please check SmartVINCENT for incentive eligibility. Retail Order Prioritization Violations This program is built on trust and cooperation between Ford and our dealer partners. There will be a zero-tolerance policy for dealers if it is determined that false retail orders were submitted in order to receive incremental allocation. The program will be audited by a third party to ensure consistency and compliance. One violation will result in the dealership being excluded from the Retail Order Prioritization program moving forward. ELIGIBLE VEHICLE LINES All vehicle lines (excluding Mach-E, Bronco and specialty units) are eligible for verification and incremental allocation through the COVP process. • Mustang (Non GT500 or Mach 1) • EcoSport • Escape • Edge • Bronco Sport • Explorer • Expedition • Transit • Transit Connect • Ranger • F150 • Super Duty COVP PROCESS • Customer places eligible retail order through their local dealership • Dealership will enter retail order into COVP website located at https://2 points

-

Yes, and since that isn't a signed agreement, I am under no obligation to pay any inflated price...hard no and I will just walk away from the deal.1 point

-

1 point

-

I switched to the ultimate lariat and added the led lights. Kept the trailer assist tho. I love the 360 view. Don’t really plan to use the knob to back the 5er but whatever. I also added upfitter switches cause why the hell not. I can use them to turn on the dc to dc charger on the camper. These forums are a bad influence. Now I have ambient lighting and fancy stuff.1 point

-

Isn’t that pretty much true for all full size half ton pickups (except maybe Nissan)? Objective differences are minor and it comes down to brand preference, subjective preferences on design and features and pricing. IMO.1 point

-

Ten minutes after my last post I got the E-mail its scheduled for the week of 11-29 YEA1 point

-

I noticed Schwab moved Ford from a D to a C rating on their A through F scale. I agree- Ford still has massive problems with huge capital needs to retool and parts shortages, but by taking a lead on electric cars and actually delivering them Ford may have a bright future.1 point

-

Before Covid, Ford was doing one time special dividends instead of raising them every year. Good way to keep the yield low. The Ford heirs love their dividends so I expect Ford to always keep a dividend when profitable and offer one time special dividends every now and then instead of raising it every year. Now with this big shift to electrics and huge, new battery plants, I don't see dividend higher than .10/quarter. This shift will take many years and cost many billions. Ford is still in the early stages and I hope this is the last dividend increase for many years. A special, one time dividend every now and then...fine, but no yearly increase.1 point

-

Sorry if I’m the wrong caliber of member. It was an honest mistake and not from being lazy about the rules. I won’t bother you anymore.1 point

-

1 point

-

1 point

-

I'm not sure where some of those guys ended up. The ones I knew stayed with the company and just worked on Medium Duty. As far as Navistar and EPA goes, Navistar deserved even more of a royal screwing than they got. They should have been shut down or, at minimum, told to buy all non-compliant engines and lemons back. Several of my current customers sued Navistar over their engines....and won or got hefty settlements or alternative arrangements made. Navistar knew darn well what they were doing, and that is the reason Cummins walked away from them because they told Navistar their "technology" doesn't work, yet Navistar continued down the Extreme EGR path anyway. If they reversed course and went to SCR they would have been 2 years late to market and would not have any trucks to sell in 2011/2012MY, so they decided to try and cheat the system with their own flawed engines, instead. One of my customers, who has 100 trucks and are complete morons when it comes to accounting, bought 50 lemons from Navistar in 2012/2013 and the settlement was just finished 2 years ago. What was the settlement? Given this company completely mismanages cash and has no financial sense whatsoever, they typically buy trucks from those who can magically arrange financing for them. So the settlement with Navistar was they would drop their lawsuit if Navistar sold them 50 trucks over a 2 year period, at discounted price AND agree to finance every one of them with a 5 year FMV/walkaway lease. Navistar agreed and case closed.....LOL....1 point

-

This information is completely wrong, Ford has always separated stock orders (20-99) from retail (customer) orders (10-19). The only thing COVP does is allow Ford to prioritize retail orders and bypass the normal dealer allocation rules. It also prevents dealers from playing games with fake customer orders. Please leave the details to ice-capades. You’re just confusing people.1 point

-

It's not common but there are times when customers (Retail or Fleet) require vehicles to be drop shipped at another dealership location for delivery. Adding a drop ship location for a scheduled order requires changes that can only be made by Ford which may, or not, be possible depending on the lead time and other factors. Making the change request would require contacting the appropriate Ford representative that can either authorize the drop ship change or contact the Ford manager that can authorize the change. It's not a simple matter of Ford helping out. Simply a matter of whether they can execute the change to add the drop code location depending on the lead time.1 point

-

At the risk of sounding like a Monday morning quarterback...... I believe the 'mistake' of the HN80 program was not selling it to Freightliner shortly after introduction. The mistake was not cancelling the program entirely before any real money was spent on it. The Louisville might have been getting a bit dated by the early 90's, but remember it's major competitor, the Mack R, was 5 years older and still selling well. No question KTP was nowhere near it's full profitability potential building heavy trucks and retooling it for Super Duty production was absolutely the right move. What Ford should have done was not bother with HM80 and continue with the old Louisville at KTP until retooling for the Super Duty in 1998. Whatever they got from Freightliner for the HN80 was probably less that what they spent on the program. I remember hearing rumors around the time HN80 was introduced that the program was late and way over budget. If true, I wonder it that had anything to do with Ford selling it off so quickly. Cut your loses and run?1 point

-

1 point

-

I had the 2014 ram eco diesel with the dial shifter.. I cant tell you how many times i put my RADIO IN REVERSE when a good song came on.. Hated it.. Now paddle shifters on the wheel.... or at least the ability to shift it there.. HELL YA.1 point

-

"I"...Re your comment on early 90 rumors, I would have to believe that the decision to spend all that money on HN-80 was made during that time frame-given truck came out in 96?? And Poling was guy at top then?? (When HN-80 was approved?) One of the things that really bothered me (as a stockholder as well as Ford truck diehard) was the truck was on the market two years and they give the business away? Once again I guess Jac the Knife carried that vote given his "most profitable wins out" mind set versus any thought about a broad product slate. As for your comment on "Baby 8-go big or go home", no argument as you worked there-me? I'm a "civilian" but I always thought that a market existed for low cost tandems-either because they were low annual mileage vehicles and/or they were in an application where the chassis was more of a "platform" for like a boom. bucket, Vactor etc. Back to Detroits, one of the best "bang for the buck" Fords I ever bought were some LN-9000 tractors, 6-71, 238's, RT-910 Road Rangers. They typically pulled short pups and replaced mostly 9000 Whites-which were nice trucks but they were powered by V-185 Cummins V-8s that were a disaster. Drivers loved those Fords!1 point

-

Theres a good YouTube video showing the steering wheel change. Was really only 15 minutes once the tools were gathered. 15/16 on a wratchet, long skinny Allen wrench to push in and release the airbag retainer clips, and I think a 10mm to disconnect the batteries is all that's needed. New wheel comes with a light grey trim and I removed it and reinstalled the black trim from my wheel1 point

-

I got to see the '22 over the weekend at the auto show, and the updates looked great. The new back end is definitely more refined looking - they nicely had the '21 on the floor on a diagonal from the "pedestaled" '22, so it made for a good back and forth look at both simultaneously. I think Automotive News' timeline is off, but they're claiming a new Navigator is arriving for '23, while they had a new Expy for '24. To me, this could be 3 things - 1) a year off, and both are '24, 2) a "straddle" debut like '15 Edge and '16 MKX were in that Edge came out in '15, and MKX was only a few months later but made a '16, or 3) means Navi comes a complete year earlier than Expy, which also explains why Navigator's refresh was more mild compared to Expedition, with it's replacement sooner on the horizon. On a related note, also saw the '22 Expy, and the interior looked much better and more appropriate for the vehicle compared to a mostly direct copy from regular F-150s the 18-21 has.1 point

-

I added a set of billet aluminum spacers on the rear. I didn't like how much the rear tires were tucked in compared to the front. Now they are much closer to the same. Also, this is going to sound crazy but if you notice in the side profile photo of my Bronco in my last post the rear wheel on the driver side is missing the small 4WP decal from the simulated bead lock on the outer rim. I called 4 Wheel Parts to try and get a replacement decal for that wheel. They had no idea how to do that so they transferred me to a gentleman named Alex at Pro Comp who actually manufactures the wheels for 4WP. Alex checked and could not find a way to get just the decal either so he is sending me a complete replacement wheel! He said I could keep the other one and use it for a spare. Wow! Talk about customer service!1 point

-

1 point

-

Finally got around to replacing the remainder of the valve seals this afternoon then took it out for about a fifteen minute drive. No more embarrassing Cheech & Chong "Up In Smoke" nonsense.1 point

-

1 point

-

The two-door Bronco that Ford had on display at Carlisle this past weekend had a set of running boards. That might be something that could be modified to fit the original Broncos and would look better than some of the pipe options IMO. Here's a super nice early model that was also at the show. This one had the James Duff rock sliders which I also like.1 point

-

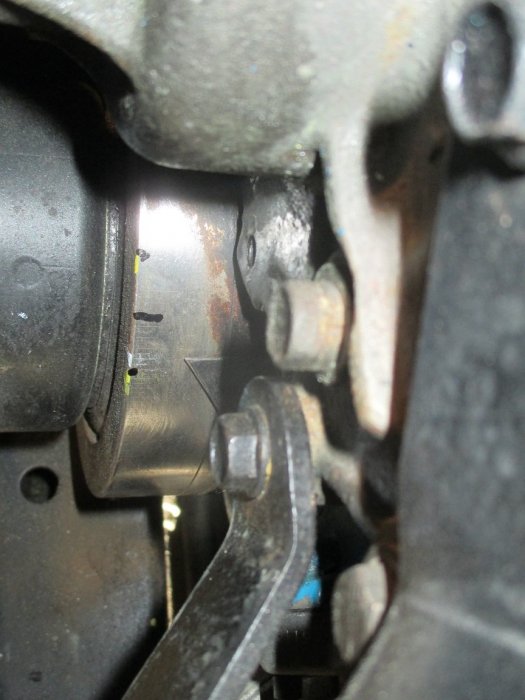

I finally got around to putting a timing light on it. Before that I decided to make a piston stop so I could verify that the timing marks on the crank balancer were correct. They were off by about 4°. The stop is made from an old Autolite spark plug. I removed the guts and then tapped it for 3/8-24 threads and installed a long bolt. The way it works is that you pull the plug for No. 1 cylinder, install the stop and turn the engine over by hand until the piston bumps against the bolt, then mark where the pointer is on the balancer. You then turn the crank in the opposite direction until it hits the stop again, then mark that spot as well. You then measure the distance between the marks, divide in half and mark the balancer at the midway point. That is TDC (Top Dead Center). Once I had that established I could see that the timing was about 4° retarded which explains why it was running a little warm. I reset the timing to about 6° BTDC with the vacuum unplugged from the vacuum advance canister on the distributor. What you see in the photo is about what you would see with the timing light at idle after the vacuum is reconnected to the distributor. After all that it now starts immediately, idles at 180° and no longer tries to diesel when I turn off the ignition. That had more to do with the idle adjustment on the carb being set too high but it wouldn't idle at a lower setting until I got the timing set correctly. What causes an engine to "diesel", or try to run backwards when you shut off the ignition is usually some carbon deposits in the combustion chambers along with a slightly open throttle. An IC engine can't run without air, fuel and spark. However, if there are hot spots in the combustion chambers they will act as the spark even after the ignition is off and the engine will try to run in reverse if it has enough air and fuel which makes it critical that the throttle adjustment is set as low as possible at idle. Back in the early days of emissions tuning the manufacturers set the timing and carb adjustments for lower emissions and would install a throttle solenoid switch which would hold the throttle slightly open so that the engine could idle but when the ignition was turned off it would retract and allow the throttle blades to close completely and thus prevent "dieseling". I've been running it around on the property quite a bit just trying to get all the bugs worked out. Next up will be to get it registered and inspected so I can put some real miles on it. After I hosed off some of the mud I couldn't resist making another short video.1 point

-

The building is 40ft x 50ft x 14ft at the sidewall eaves. It came from Olympia Steel Buildings in McKees Rocks, PA. I got a helluva deal on it when I bought it back in 2016. I paid $12,900 for the kit but that didn't include windows or doors but it did include the metal framing for all of those. That price also included shipping and PA sales tax but did not include erection. For that I hired a local Amish crew who also helped with pouring the concrete floor. I installed the doors and windows myself and designed and built the office and overhead storage loft myself with a lot of help from AutoCad and the loader bucket on the Kubota. I also modified the design by adding a block foundation which I laid myself. These typically sit on a concrete slab. The Kubota also did all of the landscaping which included tree stump removal and digging footers, floor drain ditches, etc. The inside photo is not long after I finished the loft and before I wired the building for electricity. The loft is on the end closest to the house and is pretty much full of junk now. ?1 point

-

Finally got around to firing up the Bronco again after the latest round of changes. Temp gauge held steady at just below 180° after about ten minutes of idling and driving around the lot. The steering also works like it's supposed to now after repositioning the idler arm.1 point

-

Update on the new radiator delivery: FedEx tracking shows that the driver decided not to attempt getting to my house yesterday afternoon due to a "weather event". Odd thing is that it was sunny all day yesterday and had I plowed the lane in the morning even though it didn't really need it. So, knowing that we would be getting a couple of inches of snow today I requested that FedEx deliver the package to a "local" Dollar General today which is still about ten miles from my house. That was the closest FedEx drop off location. The last time FedEx delivered a package to my house the conditions were no better than they were yesterday. I talked to the driver that day and told him that anytime the lane was not passable he could leave my packages at the neighbor's house at the end of the lane. I even watched him write that on his notepad. The problem with FedEx is that they seem to have a different driver every time I get a delivery. I removed the old radiator and fan yesterday.1 point

-

Thanks tbone. I need all the encouragement I can get. And thank God for small victories. After fooling around with the doggone horn off and on for days I finally got it working again. As I mentioned before, I had ordered a new horn button for the steering wheel. I did that because I was able to get the horn to blow at least once by touching the two wires inside the steering column together which told me the horn itself was not the problem, or so I thought. The new horn button came today so I installed it and .......nothing. WTH? I took the wheel back off and touched those same two wires together again and....silence. So I ran a jumper wire from the battery to the hot side of the horn and, again, nothing. Next I grabbed a new horn that I bought for the '70 Mach 1 that was still in the box and checked the resistance across both horns with a multi-meter. BINGO! The old horn showed zero resistance while new one read about 14 OHMs. After installing the new horn and the steering wheel with the new button the horn works like it's supposed to. That should be the final item I need for PA state inspection, although I do plan to disassemble both front hubs and re-grease the wheel bearings.1 point

-

I got sidetracked for a few days while I installed a new garage heater. This one is a Mr Heater 50k BTU ceiling mounted natural gas unit. Works great! The old heater was one of those wall mounted, unvented, open flame CO generators. In other words, a death trap. Anyway, I finally got around to pressure washing the engine bay and wiring the back-up lights. I had to buy a pigtail for the back-up light switch on the NV3550 5-speed transmission. Then I had to figure out where the old wires were and how to tap into them. What I discovered was that when a previous owner converted the original 3-speed to a floor shifter they also replaced the steering column with one out of another Ford vehicle that had a floor shifter which meant they got rid of all the shift linkage that would have been on the old column. That was a good thing except for the fact that they also got rid of the column mounted back-up light switch which explains why the back-up lights have never worked since I bought it. Not a big deal with the NV3550 other than finding the old wires and connecting them to the new back-up switch located on the side of the NV3550. Other than some more grounding issues in the taillight housings it was actually easier than I thought. They only come on when the shifter is in reverse and the ignition is in the RUN position which is exactly the way it should be. I have also been fooling around with the horn. What I discovered was that whoever installed the aftermarket steering wheel didn't wire the horn button correctly which resulted in lots of sparks and a melted connection on the horn button. I have a new button ordered.1 point

-

I found another source for the rock sliders, James Duff Inc. which is also where I bought the hood strut kit. These are very similar to the Wild Horses design with one major difference, these are also attached at the pinch weld between the inner and outer rocker panels. They are made from your choice of either 1/8" or 1/4" thick steel plate and come with a 3/16" thick plate that mounts on the inside of the inner rocker. In addition to being bolted to the outer face of the rocker they are also bolted through the pinch weld and the 3/16" plate which adds enough strength that the manufacturer says it is okay to use these as steps. As you can see from the photo, their simple solution is to use anti-skid tape on the pipe. They also come with nutserts for the outer bolts and an installation tool for the nutserts. Their price is a little higher than any of the others of this design but because they are located in Tenn and not on the west coast the shipping cost is less which makes the overall price competitive, especially considering the extra features and tools.1 point

-

Thanks. I still haven't finished the passenger door, or the hood struts, or changing the oil, or.....?1 point

-

I've kept just about all of the receipts for parts (I think) but I couldn't even begin to guess the amount of time I have spent on it. To be fair I would need to include all of the costs incurred on this years ago when I did the drivetrain and suspension changes, among other things. Bottom line though is doing this kind of stuff truly is one of my favorite hobbies and if I kept track of all the expenses I would probably be disappointed in the end result and that is not the goal. I have friends who started out building project cars for their own use but eventually started building them just to sell and make a profit. Just my personal opinion but at that point it would become too much of a business (i.e. job) and would no longer be as enjoyable for me. Don't get me wrong, I'm also not into spending (or wasting) unlimited amounts of money that I don't have anyway. One of the things I enjoy most about these projects is finding the parts I want for the best price. Sometimes you have to put some sweat equity into making them useable but for me that's a big part of the fun. The roll bar is a perfect example of that . I got it as part of the deal when I bought my '70 Mach 1. I have spent an ungodly amount of time cutting it down and cleaning it up. I could have just bought a brand new rollbar and bolted it in but would not have gotten the same satisfaction. BTW, that storm that came through here yesterday dropped 21" of snow in about 14 hours.1 point

-

1 point

-

I may need to modify the mounting brackets to try and tuck these up as close as possible to the rocker panels which should look a little better as well. The fact that my Bronco has a 2" body lift will probably make modifying the brackets even more of a necessity. I also decided to swap buildings and parking spots today with my '68 Cougar. The steel building has the bigger air compressor and other tools to get me to this point but no heat. I'm still waiting for the clearcoat to cure so I can wet sand and polish it and I'm hoping the heated garage will help to speed up that process. Everything else is just reassembly work after that and now that winter seems to have set in the heated garage will also be a much nicer place to work. There's that age thing again.1 point

-

I decided to try a different design for the "rock sliders" or "nerf bars". I initially planned to use the ones from Wild Horses but decided instead to go with this set from Aries. I still like the look of the WH design better but sometimes looks aren't everything. The biggest issue is that the WH bars are not designed to be used as steps. I assume that is because they attach to the sheet metal of the rocker panels. The Aries design is made from 3" powder coated pipe and attach directly to the frame rails. They are also a direct bolt on and do not require drilling any holes in the body. It also doesn't hurt that they are less than one third the price of the WH design. I may lose a little ground clearance but there aren't many places to go rock crawling around here anyway. The Bronco has a 3.5" suspension lift, 2" body lift and sits on 35" tires meaning it would be great to have something I can actually step on besides a step ladder to help me get into it. I must be getting old. ?1 point

-

Started adding a little color today. I'm spraying the quarter panels and passenger door off the vehicle. I'm not confident enough to risk spraying those large vertical surfaces while on the vehicle. By laying them flat I'm not fighting gravity as much and way less likely to get sags and runs. I mounted the passenger side quarter panel back on the Bronco temporarily since that is the safest place to keep it. So far I've done the base coat on both quarters, both door jams and both rocker panels. The passenger side door and top half of the tailgate will get color next and then I can start spraying the clear, shiny stuff. In case you haven't figured it out yet, this is definitely a low buck, do it yourself operation. ?1 point

-

You've asked that question before and the answer is still the same. If there's anything I have learned about body work (which admittedly isn't much) it's that haste makes waste and patience is way more valuable than speed. ? In case anyone was wondering, here's why there are three shift levers sticking out of the floor. The tallest one controls the NV3550 five-speed while the other two control the original Dana 20 transfer case. That's what is known as a "twin stick" conversion. The way it works is that each lever controls the power going to each axle and you can do that somewhat independently of each other. In other words, you can run with just the rear axle engaged, just the front axle, or both. And, you can run either axle in high or low range. That can obviously be both good and bad. It is good in that you have the option to use only whichever axle has the best traction available or is needed to maneuver in a tight situation and you can do that in whichever gear ratio is needed (1:1 high range or 2:1 low). It is bad in that you don't want to have both axles engaged at the same time but one in high range and the other in low. If you do that you WILL break something. Probably a good reason why they never offered the twin stick option from the factory. The whole drivetrain combination works surprisingly well. When you combine the torque output of the 393 cu in V8 with the 4.01:1 first gear ratio of the NV3550, the 2:1 low range ratio of the transfer case, the 4.11:1 axle ratios (the Dana 44 front axle is actually 4.10:1), the Detroit Locker in the 9" Ford rear differential and 35" mud-terrain radial tires, this thing is an off-road beast. The NV3550 also has an overdrive fifth gear ratio of 0.78:1 so highway performance isn't too bad either. The one change I might consider in the future would be switching from the 750 cfm Holley dual-feed carb to a Holley Sniper or similar throttle body FI system. Another interesting option might be the multiport fuel injection system from the original F-150 Lightning which also used the 351W block.1 point

-

Sounds like a terrible life you have there, lol. The “choice words” help every project go smoother. I do like the rock guards.1 point

-

Did some farting around with the driver side door today. I rebuilt the upper hinge (new pin and bronze bushing) and replaced to lower one with one that came with the used red doors. I did have to make some extra shims out of sheetmetal to use between the hinges and the door jam. I think I have it about the best I can do for now. The rear bottom of the door doesn't align very well with the back end of the rocker panel but I think that is because whoever replaced that rocker panel before I got the truck didn't get it installed too straight. I plan to add a set of rock sliders and they will cover that entire area anyway as well as add a step. I added a photo of the sliders I plan to buy. One little issue I had was trying to adjust the back of the fender. The rear most fender bolt threads into a nut-sert in the inner fender. It was so rusty that I couldn't get the bolt in far enough to hold the fender in place. So...I had to run a 5/16-18 tap through the nut-sert but the only way I could turn the tap was with a small adjustable wrench which took forever along with several choice words.1 point

-

More photos. I decided to salvage the edge of the old steel corner cap and epoxy that strip of metal to the edge of the fiberglass to close the gap where it meets the tailgate. Not super confidant this will work since those two materials will expand and contract at different rates and the whole thing could eventually crack at the joint. I also used 'glass reinforced Bondo on the outside to fill in the seam. It is now in primer. So far so good as it has endured all the sanding and trial fitting without any cracks. The next step will be to add a few layers of 'glass mat and resin to the inside of the joint. Worst case if it does crack I will have to duplicate this edge with all fiberglass. IMG_4075 shows the gap at the tailgate after adding the steel strip. Anyway, I also added a bracket on the inside of the fiberglass so I could bolt the lower rear corner of the quarter panel to the body. There is a series of holes along the top of the quarter panel where the steel top bolts on and where the convertible top frame will eventually be bolted on. There is also one sheet metal screw at the very bottom that attaches the quarter panel to the door jam and rocker panel meaning the entire quarter panel will be removable similar to the front fenders. I plan to eventually paint the entire inside surface of the quarter panel including that bracket with Eastwood Chassis Black. The steel body tub under the new panel will get a fresh coat of POR15 topped with the same Eastwood paint.1 point

-

Latest: I cut out the opening for the fuel filler tube. Got lucky and just happened to have the correct size hole saw. I also draped the soft top over the old steel top so you can get a rough idea of what that's going to look like. Keep in mind that the whole truck will eventually be back to same color of green and the missing pieces of stainless trim will be put back on the quarter panels and passenger door. The top has been stored in a plastic bag for years so it's going to take some time and a good scrubbing to get all the wrinkles and crud out of it. Like I said before, the top also came with a folding frame. I'm still debating whether I want to put the side marker lights back on the quarter panels. Whoever did the previous bodywork didn't put them back on the 'glass front fenders either. Technically I may not have a choice since PA does have annual state safety inspections and side marker lights on both ends were a federal requirement in 1975. The good news is that all of the wiring for those lights is still there.1 point

-

Thanks. Be careful what you ask for. LOL I started doing a little more trial fitting over the past few days. I now have the driver side quarter on and removed the green passenger side door and replaced it with this red one. It may look worse right now but believe me, it is in way better condition. The green door was even dented on the inside! I also cut out the opening and fitted the taillight on the passenger side quarter panel. When I found this roll bar it had a bunch of extra tubes added to it to make a full roll cage. It wasn't all that well done. I cut most of that trash off and used it to make a cage for my 4x4 Kubota tractor. I believe this is an original Bronco sport bar which may have been a factory option. Lots of folks will argue that Ford never offered such an option and maybe that's true but I seem to recall otherwise. Anyway, the diagonal bars and the bottom bar were part of the add-ons but I decided to leave those as they are. They may hinder access to the rear seat a little but you would have to be an acrobat to get back there anyway. I'm actually leaning towards leaving the rear seat out. The extra cargo space is more valuable.1 point