PRH60

-

Posts

13 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Downloads

Store

Posts posted by PRH60

-

-

-

Volvo Trucks to acquire JMC Heavy Duty Vehicle Co Limited. - Press Release 23rd August 2021

Volvo Trucks acquires heavy-duty truck manufacturing operation in China Volvo Trucks has agreed to acquire JMC Heavy Duty Vehicle Co., Ltd., a subsidiary of Jiangling Motors Co., Ltd., which includes a manufacturing site in Taiyuan, Shanxi province, China, for an amount of RMB 0.8 billion (approximately SEK 1.1 billion). The objective is to start production of the new heavy-duty Volvo FH, Volvo FM and Volvo FMX trucks in Taiyuan for customers in China from the end of 2022. Volvo Trucks has been active in the Chinese market since 1934. During the last couple of years, the strong growth of logistics services, including e-commerce, has led to a surge in the sales of Volvo trucks in the country. In 2020, more than 4,500 heavy-duty Volvo trucks were imported and delivered to customers in China. In line with the long-term Volvo Group strategy, Volvo Trucks is therefore expanding its business operation in China. “We are committed to shaping the future of sustainable transport solutions. With our long standing presence in China, we are growing our sales, and we are expanding our strong network of sales and service points together with our private dealer partners. Over the last couple of years, we have seen a fast development of the logistics markets and an increasing demand for our premium trucks and services. To meet the demand from Chinese transport operators, the time is right for us to establish a regional value chain with our own heavy duty truck manufacturing in China,” says Roger Alm, President Volvo Trucks. The operations in Taiyuan will include stamping, welding, manufacturing of cabs, painting and the final assembly of Volvo trucks. After investment, within a few years, the plant will have the capacity to produce 15,000 Volvo trucks per year with the potential to increase the capacity further. The transaction is subject to customary closing conditions, including regulatory approvals.

-

Bob,

I have no personal knowledge of North American engineering support to the Global Cargo at Ford Otosan as I am not involved in the heavy commercial vehicle sector or associated with the Ford Motor Company. As an interested observer though I think you could conclude that the Global Cargo program is KOC Holdings baby born of an association with Ford Trucks since they began assembling the (Ford) Thames Trader truck in 1961 and later in 1966 the Ford D series trucks under licence. (D1210 model)

The late Nuri Otay recalled that Otosan worked hard to convince Ford Motor Company to become global players in heavy trucks once again following the sale of 52% of Ford Trucks Europe to Iveco in a joint venture in 1986 with Iveco subsequently taking full ownership in 1991.

"We even held discussions in June 2010 when Ford Motor Company’s Bill Ford came to Istanbul to celebrate Ford Otosan's 50th year. If you look closely you will even see that we took a photo in front of a Cargo truck. This was not for nothing."

The only North American involvement I can find with the Global Cargo program is that of John Sidelko who was Ford Otosan's truck program chief designer for the second generation H476 Ford Cargo which debuted in 2012. Also Mark Zolna who was the Global Heavy Commercial Vehicle Planning Manager between 2011 and 2014 and secured approval for the H62X (F-Max) program.

Design of the mid cycle updates for the Ford Otosan H476MCA (Cargo), H566MCA (Cargo Tractor), and the new H62X (F-Max) was largely undertaken by Ford Otosan inhouse designers, engineers with access to Ford systems, software and component suppliers such as Lear Corporation from their Moroccan and Spanish facilities

JMCH JH476 (Cargo) & JH625 (F-Max) design and manufacture at the JMC Taiyuan plant was supported by Ford Otosan engineers and other design and engineering staff contracted to JMC with external support from French company SEGULA Technologies from their office in Turkey. Exterior design was by Spanish designers.

-

1

1

-

-

-

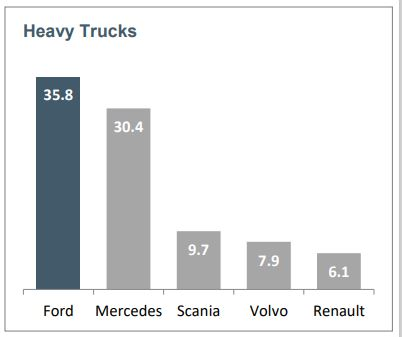

Ford Otosan has a manufacturing capacity of 15,000 heavy vehicles per annum at its Ekesehir plant in Turkey. It has doubled its market share in Turkey over the 12 year period since 2008. Ford Otosan produced 8358 trucks in 2011 for a 22.8 % share of the Turkish HCV market and in 2020 produced 7839 trucks for a 31.7% share of the heavy vehicle market in Turkey.

% of Turkish Heavy Commercial Market Share February 2021.

2008

2009

2010

2011

2012

2013

2014

2015

2016

2017

2018

2019

2020

2978

2061

4668

8358

6001

5998

6772

7842

5193

5187

3415

2370

5309

Ford Otosan International HCV Sales

1006

1008

976

1500

2200

3003

2530

Total Ford Otosan HCV Sales

2978

2061

4668

8358

6001

5998

7778

8850

6169

6687

5615

5373

7839

% HCV Market Share Turkey

14.7

17.3

18.3

22.8

20.0

21.3

21.8

23.3

28.1

27.7

28.5

31.4

31.7

Ford Trucks stated goal is to have a minimum of 5% market share in 80 countries worldwide by 2023, including much of Western Europe

The company is developing its own automated transmission and will develop a 2.3m wide version of the F-Max cab to replace the cab on the Cargo model before contemplating production of a right hand drive version.

Jiangling Motors Corporation Heavy Duty Vehicles (JMCH)

Ford Motor Company is a major shareholder in the company however it may not have a controlling interest in the company.

JMCH, although not within the top ten heavy vehicle manufacturers in China is a significant vehicle manufacturer and have invested in the localisation of the Ford trucks

JMC produce a Horizon hydrogen fuel cell 4x2 version of the JMC Weilong primemover (Cargo) as well as JMC HV5 (FMax) in tandem drive, Diesel, WeiChai NG (LNG/CNG) powered, Horizon Hydrogen Fuel Cell powered versions.

JMCH annual production in 2019 was 96,919 commercial vehicles. The number of heavy duty trucks produced does not appear to be available on subscription free sources however JMCH shows part of an order of 100 JMC Weilong HV5 (FMax) primemovers being delivered to the Fast Growing Logistics Company at a presentation in April 2020.

JMCH commercial vehicles produced include JMC light trucks with 1.5 tonne to 4.7 tonne capacity powered by Ford Duratorq 2.4 litre, Isuzu 2.8 and 3.0 litre Euro 5 diesel engines and 5 or 6 speed Getrag manual transmissions. The JMC Super Carrying light duty cab forward truck utilises a Cummins 3.8 litre diesel engine with a 6 or 7 speed manual transmission.

Light duty battery electric versions of these trucks are produced with 81 and 107 kWhr batteries for 1.2 to 2.3 tonne payload capacities.

Ford announced that the company's automotive business in China will focus on the four core areas of Ford-branded passenger cars, commercial vehicles, Lincoln-branded and electric vehicles on 28 April 2021. It established Ford China passenger vehicle division and Ford China commercial vehicle division including indicating that there would be a transformation of the commercial operational model.

On the 7th of May 2021 Jiangling Automobile Company approved the sale of 100% of JMCH for not less than $118.7M USD.

JMCH have already spun off the heavy commercial engine production into Taiyuan Jiangling Power Company Limited of which it sold a 60% share to the Yunnei Group in January 2021.

Heavy commercial vehicle sales are at a record high in China, in 2020 1.6 million vehicles were sold.

Restrictions on foreign owned commercial vehicle companies have been lifted. Hyundai, Scania are building plants. Daimler is in a joint venture with a local company to produce Mercedes-Benz trucks for the China market.

China Commercial Vehicle Network have speculated on the internet that Volvo Group may be a purchaser of JMCH assets as Volvo Group trucks are an import only operation in China.

If this were to be the case the Otosan licensing agreements would not be required.

Volvo Group have a 45% holding in Dongfeng Commercial Vehicles which produces Nissan UD derived trucks for the local market, Volvo having sold its 50% share in the Sinotruck joint venture in 2009.

From Big Mack Trucks, 30th of May 2016

Ford Otosan, Ford Motor Company and Ford Global Technologies LLC (Licensors) signed a technology licensing agreement on July 25, 2014, with Jiangling Motors Corporation (JMC) in which Ford Motor Company holds a 32 percent stake.

The agreement granted JMC a non-exclusive license relating to Ford Cargo product technology, know-how and technical documentation relating to the design, manufacture and service of the Cargo chassis, cab and related components of Ford branded heavy trucks.

JMC agreed to pay Ford-Otosan an entry licensing fee of 8 million Euros, an average 390 Euro licensing fee per unit for each chassis produced, and 39 Euros for each cab produced.

The terms of the agreement are 12 years starting from mass production (November 2017) with automatic 3 year extensions unless declared otherwise.

FORD OTOMOTİV SANAYİ A.Ş.

Associated party transactions 2019 and projected for 2020

Engineering services sales to Jiangling Motors Corporation Ltd. (JMC) is based on “Engineering Services and Technical Assistance Contract for JMCH Stage 6 Ecotorq Project” dated 31 October 2018 and “Engineering Services and Technical Assistance Contract for JMC Branded JH476 Stage 6 Heavy Truck Project” dated 31 October 2018 and 11 November 2019.

In addition, license revenue is obtained from the engine that JMC produces and uses in JH476 Heavy Truck based on “Ecotorq Engine Technology Licensing Contract” dated 22 April 2013 and from the chassis that JMC produces based on “Technology Licensing Contract For JMC Branded JH476 Heavy Truck Program” dated 25 July 2014.

The company sells heavy commercial vehicle and engine production parts to the People's Republic of China with the “Agreement of Ecotorq Program Product Supply Agreement” and “JH476 Heavy Truck Program Product Supply Agreement" dated 30 March 2017 signed with Jiangling Motors Corporation Ltd (JMC).

-

3

3

-

-

-

It has been announced previously for North America and is referred to on the 2020 Transit Overview on the Ford North America website.

-

I think you will find the statement relates in part to the replacement of the 3.2 litre Powerstroke with a 2.0 litre diesel.

-

jpd80, I think the front mule is a widened and lengthened Focus wagon not a Mondeo wagon.

-

It is obviously a mule, however an interesting point to note is that the photographs of the camouflaged Bronco mules to date show what appear to be Ford Ranger bodies not Ford Ranger Raptor bodies, which have wider quarter panels and flared guards. The Ranger Raptor has 2.5 inch blue shock absorbers which could be similar those on this mule whereas the 2019 F150 Raptor has 3 inch Fox live valve internal bypass shocks which are orange.

-

Check the area of the honeycomb grille under the letter "D" in Ford. Several cells appear blocked. Note also the colour of the shock absorbers, they are blue not orange.

-

Ford South Africa has announced that the Struandale Engine Plant in Port Elizabeth is to assemble EcoBlue diesel engines including for the Ford Ranger Raptor commencing in the 4th quarter of 2018.

Also the current component machining and assembly lines for the Duratorq TDCi diesel used in the Ranger, Everest are being expanded to eventually become the home for all Duratorq TDCI component machining for the Ranger, Everest and Transit.

.thumb.jpg.a2cf64dbe47d6109503ccee1fcb61e94.jpg)

New Light & Medium Duty News

in Ford Motor Company Discussion Forum

Posted

My understanding is that Volvo Trucks have or will discontinue the manufacture of JMCH models in Taiyuan before commencing manufacture of heavy-duty Volvo FH, Volvo FM and Volvo FMX trucks for customers in China in late 2022.

I have not found information on the current status of JMCH heavy duty trucks but would be interested to know whether they are still being manufactured.

The JMC Group annual production includes;