-

Posts

1,641 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Gallery

Downloads

Store

Everything posted by matthewq4b

-

I'm sure Ford was a little miffed that Navistar out sourced the design of the engine. But as Jp said there was little they could do about it. And both MAN and Navi kept the origins of the engine quiet. I'm pretty sure if it got out that the new Navi Diesel in the Super Duty was of German origin I'm not sure that it would have gone over well with a good portion of the target customers. As for Ford designing their own, they did not have a lot of option. Who could they go to? Cat was exiting road diesels. Ford did enter discussions with Cummins about replacing the 7.3 but it went no where and it was also off the table for the replacing the 6.4L I imagine Chrysler has them locked in for exclusivity with the 6cyl hence the reason Nissan is getting a V8. Ford was not really left with a lot of option, either stick with Navi or source an engine from a Japaneses or an EU supplier (Ford would not be able to keep that quiet) or do their own. Really the only practical solution was to do their own. The 6.7 is far better than the 6.4 but not as good as the Cummins in the Ram. Personally I would have like them to see them do an I6 instead of a V8 but i'm sure Ford had their reasons for a doing a V8 The 6.7 Ford is by far the most powerful Diesel available in a Pick up.

-

No problem Richard I was not sure those releases were still available publicly.

-

OK I found an out. JPD Navistar just had to supply an IH manufactured engine to Ford which they did No one built the 6.0L for Navistar they just did not do the design on it. As for Richard Need to lay some back ground here, In 1996, PACCAR acquired DAF Trucks out of bankruptcy In, In 2000 Daimler/ Frieghtliner Acquired Detroit Diesel in, 2001 Volvo AB acquired Renault Véhicules Industriels and in turn Mack. This latter deal added Mack to the existing Volvo AB North American operation. Daimler's preferred engine was now Daimler-owned Detroit Diesel. Given that Freightliner, Daimler North American truck brand, had considerable market share, this gave both Caterpillar and Cummins reason to think as a significant part of their respective market had potentially been removed. For Volvo the acquisition of Detroit Diesel was welcomed as here was an opportunity legitimized by Daimler's action to pursue business in NA by with its own engine range. PACCAR was probably more nervous, but had some comfort from its existing European engine manufacturing operation. DAF in Europe had been more reliant on engine supply than many of its competitors but it could at least claim to have a Plan B should supplies dry up. Now this also impacted CAT and Cummins but we are just going to concentrate on Navistar. Navistar watched the events during 2000 with some trepidation. Regardless of their expertise in Medium Duty engine production, they were wholly reliant upon supply for its Heavy Duty range. Unlike Volvo, Mack, PACCAR and Daimler Freightliner, it had no other place to go for in house engines. Navistar needed to ensure engine supply, furthermore with the impending increasing restrictions on Diesel emissions Navistar had no practical experience with ULSD motors or cleaner Diesel technology unlike the other Heavy truck manufactures that had EU operations or owners to glean experience from. . During 2000 Navistar approached both Volvo and Cummins to ensure a continued supply of engines and shared development of Diesel emissions this proved unsuccessful and negotiations with both were suspended in 2001. Navistar was getting increasingly desperate to find a partner to insure a continued supply of engines and glean experience with clean diesels. Thus entered MAN. MAN designed & manufactured on road engines from 50hp to 1,8000HP in 4cyl I6 V6 V8 and V12 configurations additionally they sold and manufactured their own line of trucks and buses and military vehicles under the MAN brand name and OAF , they also provided design work for other manufacturers In addition MAN designed and manufactured off road, power generation and ship diesels. MAN a leader in clean diesel technology was looking to increase sales in it's commercial vehicles division, but with the recent rash of mergers it appeared that there was not going to be a lot of opportunity to increase sales of their on road power plants. MAN and Navistar had no competing products in their portfolio's and both were looking for what the other had to offer. The first order of business was to get a replacement for the T444E designed and built to meet the up the coming switch to ULSD and tighter emission controls this design project was given to MAN commercial vehicles division with manufacturing to reside with Navistar In NA as the first tentative step in forming a mutually beneficial collaboration.. This project was intended to be to be a direct replacement for the T444E and the then future VT365 was designed as a medium duty diesel who's primary application was to power Navi owned IC school buses and IH medium duty trucks with that emissions regime accounted for in the design. During testing of prototypes MAN found out Navi was also going to be be suppling Ford this engine for the light duty F Series this was a point of concern with MAN as this design was not intended for that emissions regime although capable of meeting those emissions they were not the parameters the engine was designed around MAN had concerns that the engine my not be entirely satisfactory for that application given the reduced emissions and proposed increased HP in the Ford application. Either the increased HP or the reduced emissions would have safely fallen within the design parameters but not both. By that time IH had already made commitments to Ford for delivery of the 6.0L. Thus negating any opportunity of redesigning the engine. MAN designed an engine to replace the T444E not the 7.3 power stroke. MAN and Navistar continued to work on other various projects and entered in to discussions about formalizing it. This culminated in a collaboration pact with MAN for Product Design, Development, Sourcing and Manufacturing in late 2004. It saw MAN agree to supply its D20 and D26 engines to Navistar. And In 2005, Navistar acquired Brazilian engine manufacturer MWM Motores. , this provided Navistar with a lower cost production site for the MAN D20 and D26 engine blocks, which would then be dressed in the Huntsville plant. http://ir.navistar.com/ReleaseDetail.cfm?releaseid=149889 http://ir.navistar.com/ReleaseDetail.cfm?releaseid=156189 http://ir.navistar.com/ReleaseDetail.cfm?releaseid=160201 The 6.0L/VT365 was a MAN designed engine manufactured by Navistar just as all (in part or fully) the new Navistar engines have been for the last ten or so years The MAN design influences are quite apparent in the VT365/6.0L, especially in the long bock assy. Between 2011 and 2012 Volkswagen took controlling interest of MAN SE the parent group of all MAN subsidiaries.. SO.... technically you can now blame VW for the 6.0L not being able to perform correctly and meet emissions. And you all thought this side bar had nothing to do with the original topic ;-)

-

Yup all related problems in short when the engine was dropped in the Pick all this stuff cropped up. The blue spring mod again is a Ford application issue it is not an issue in the VT365 as the fueling requirements were not as high. The fuel injectors also suffered from this. Ford asked Navistar to supply an engine and they did. Ford had no idea that the engine was not suitable as engineered for their HP and Emission specifications. Just a couple points. The EGR cooler cooler change from tube style to radiator style was done because EGR gas temps were to way high entering the intake. The stock unit was not cooling the gasses enough in the Ford application due to the higher EGR cycle. The location of the FICM on the valve cover at the time was not uncommon at the time for EU truck engines. Daimler, Scania, and MAN all mounted their injection control modules in the same or similar locations with out issue. FICM failures in the VT365 are not very common. It was marginal piece from the get go no question there. But perfectly serviceable in the designed application. In the tighter engine bay of the Ford with higher peak engine temps this marginal piece was failing. . The 6.0L was good engine as designed for the application Intended it fell apart once the emissions were increased and the HP raised do either or separately and again you wouldn't have the Issues that plagued it.

-

Yup they choose to cheat there are many reasons why they did choose to cheat but in the end they did. And it is going to cost them in fines, reputation, lost sales, law suits, and technical advancement as they sat idle relying on software and not advancing the hardware. There really is a similar parallel between Diesels now and when gasoline emissions were cranked down, it is interesting to witness the technical advancements and each company is tacking them, how some are cheating either a little or a lot. This currently is very similar to the early 80's for gasoline engines. We are now seeing HP's creep back up and efficiency creep back up with new tech on the horizon. I think the whole industry is on the cusp of some major changes. We have Hybrids ,full EV's clean diesels making in roads (look where diesels were 15 years ago compared to today), gasoline engine tech is advancing too and the hiccups that are coming with it. I doubt we will recognize the auto industry in 15 years from what it is today. All in all it is an interesting time.

-

It was not uncommon for EU diesels to use Engine oil to drive the injectors it was more the norm rather than the exception in the era hence the reason the 6.0L ended up with this system. The stiction issues are a combination of poor fuel and poor oil and or or infrequent oil changes. If I recall correctly the 6.0L came from ford with a conventional 15-W40 from the factory it was the base recommended oil for the 6.0L, it really should have been full synthetic EU diesels of the era were using full synthetics and I imagine that is what the designers intended for it. . The deposits from conventional oils certainly helped contribute to stiction issues, Shell Rotella T6 5w-40 is great oil for the 6.0L and with some Revx added will help with eliminating stiction over time. The 6.0L was designed for the much cleaner ULSD so i'm sure the pre ULSD diesel did cause some issues but i belvie that over heating of the oil and injectors caused most of the problems. One of the big killers of 6.0L injectors is fuel starvation and that is due to failing to change the filter in the fuel conditioner (the fuel filter every one forgets about) on the drivers side frame rail. This starves the injectors and is a another cause of the injectors overheating as the fuel helps cool and lubricate them. That filter is also the water separator if that filter becomes plugged either with crud or water it will starve the injectors and they will quickly burn out. It should be SOP to crack the drain plug on the fuel conditioner with each oil change, if any amount of water is found in it replace the filter.

-

Here is a list you pick Scania MAN MTU (Now RR Holdings) Daimler AG Iveco All of the above had the technical know how to design the VT365 at that time. The Europeans were years ahead of the domestics at that time in terms of designing and building cleaner diesels , It remains so today as most of the passenger and light truck diesels being sold in NA have EU roots. Just do a search to see who Navistar has collaborated with in the past from the above list

-

All great points Blwnsmoke. But the head gasket issue and the HPOP issue was directly related to emissions and will touch on that in a bit. The sand casting issue was a manufacturing issue and the VT365 experienced this also in the early motors. Even though the engine was an EU design it was built by Navistar. The Gold coolant was a complete fail on Fords part it is not a dedicated Diesel coolant it does not have the same anti-cav properties of Diesel coolants not the heat transfer capability's of it. This was compounded by the tighter emissions. The Cat ELC coolants is probably the Diesel coolant on the market. And all my diesels even the Mercedes ones run it. We also had the failed injectors in the 6.0L and failed FICM's ( Fuel injector control module's) again IH did not have this problem in the VT365. It was a direct result of emissions. What killed the 6.0L in the Ford trucks was..... heat. And that was direct result of the tighter emissions. The VT365 in the IH products does not suffer Head gasket failures EGR cooler failures FICM failures,injector failures all are not common. and quite rare In the Fords all this was due to heat. So what is different from the VT365 and the 6.0L essentially nothing. Except calibration and there in lies the culprit. And what is different ? EGR cycles and injector pulse. So lets look at the EGR issue. First off you have to understand the 6.0L is easly capable of generating 1250°F exhaust temps pre turbo. Where are the EGR gasses drawn from ? Just before the turbo. The EGR gasses of course cannot be fed in to the engine at over 1000°F so they go through a cooler to cool them so this exhaust heat is dumped in to the cooling system. In the which in it's self is not an issue if the coolant system is designed to dissipate this extra heat.. Which it was in the VT365. The issue came with the Emission calibration for pick up trucks. In that application the EGR valve had much much higher duty cycle meaning it was open way more often dumping way more heat in to the engine compared to the VT365. The Ford trucks did not have proper temp gauges what is there is not much better than an idiot light and no EGT gauge so you really had no idea how hot things actually were. Further more the Oil is cooled by the coolant,all this extra heat was put in to the Oil, the coolant, the injectors (cooled by engine coolant and driven by engine oil) the heads the block the turbo HPOP etc etc. This was compounded by Fords use of Gold coolant and not proper Diesel coolant this made the heat saturation issue even worse. It was entirely possible in the Ford application to overheat the EGR cooler so bad that it would form a steam bubble inside it stopping the flow of coolant and melting it's internals causing it to then leak and dump coolant in to the combustion chambers, this extra heat stressed Injectors causing failures and ramp'd up the amperage needed to drive them this in turn resulted in FCIM failures. This extra heat in the oil also over stressed HPOP's causing the early aluminium bodied units to fail the revised all steel ones lasted much better. All this stressed the heads and gaskets and caused failures. Every single 6.0L with blown head gaskets has warped gasket surfaces with out exception. Since they knew this engine was going to operating at higher temps and under more stress the amperage to the injectors was upped this over stressed the FICM's causing FCIM failures and injector failures. The FICM calibration has been changed more times than i can count to try to counter this. That is what killed 98% the 6.0L's in Ford trucks a higher EGR duty cycle in a system not designed for it. It is that simple. The VT365 in IH use is a very reliable engine, no blown head gaskets no EGR cooler failures no wasted FCIM's or injectors. These issues are very rare in the VT365. How can you fix it ? One thing that must be done is dumping the Ford gold coolant and replacing it with Cat ELC. The second is disabling the EGR valve. This can be very easily with an SCT tuner. It does not disable the EGR valve 100% it is active at low engine RPM"s and light load situations such as Idle and coasting. But it's use is reduced by about 85%. These 2 small changes will stop 99.9% of the 6.0L issues in 90% of pick up trucks. There are all kinds of after market kits for the 6.0L remote oil coolers remote oil filters egr deletes none of this is needed unless you are really going to be pushing the truck IE drag racing or doing lots of high speed very heavy towing. The ARP studs are good insurance but are not necessary in 90% of trucks.. Personally If you are doing head gaskets put in the studs but that is me personally as I have never been a fan of torque to yield head bolts ,I just feel torque to yield bolts are not good in dynamic applications but that is me.. Also make sure that FICM has the latest revision of software this has helped with injector failures by changing the injector pulse and not driving them as hard.

-

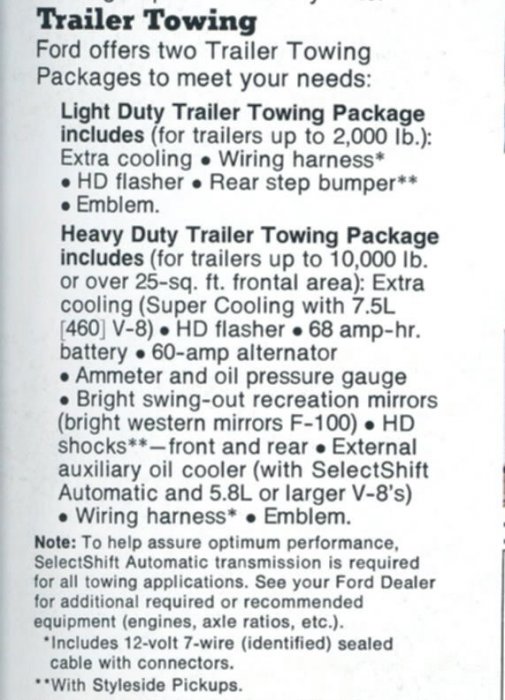

290 Ft Lbs for the 351W and 262 FTlbs for the 351M the Windsor was not always available and was not nearly as common as the 351M 1994 the 300 Six was putting out 260 Ft LBS again lower gearing 5 speed Manual or 4 speed auto and and being an I6 means a much much broader and better torque curve. And no the tow package on all for ford Full size cars since like forever was 5000lbs even the last iteration of the Panther was rated to 5000lbs with the tow package this lowered in the early 2000's to 2500lbs Heck my old Marquis was fitted with tow package for up to to 5000lb trailers. The Max tow rating for the F150's in the 70's was 10,000 Lbs ya seems almost unbelievable but that is what it was. Ford had what they called heavy half's they were in essence a 5/8's ton truck and these were rated to 10,000lbs towing. Here is a snippet from a sales brochure of the era.

-

And that was just one Example and pretty detailed one hence the reason for providing the link. It was meant to be proof. Seriously Richard you are really grasping. You got a computer and the internet do a search. Here I'll help you out "VT365 European" there ya go. The VT365 was designed by a leading EU diesel manufacture they at the time were at time were leading the industry in emission Diesels and had already adopted SCR in 2003 for some applications in addition they and design and supply .engines and vehicles for third Party's I bet every one else here can figure it out. Care to hazard a guess ? I bet the first person that does nails it. This is not rocket science to whom it was I can not say due to employment disclosure reasons. Simple as that. Choose not to believe it that is fine I don't care no skin off my nose. IH went to them for the design of this engine simply due to the fact that IH had ZERO experience in designing ULSD diesels and they needed this engine yesterday. So the design was farmed out to a company that had extensive experience designing on road ULSD emission diesels. It was never disclosed this engine was going pick up trucks that had a much tighter emissions requirements and see much more abuse. Don't believe it, Don't care. Not my loss. And you can go on being sheeple.

-

I never said that. That was Akirby. And actually the Diesel emission regs are pretty much where they should be. They have been pretty much on par with keeping pace and forcing the development of Diesel emission reduction technology with out stripping it to badly. VW chose to cheat to supply what they perceived as a superior product (in terms of power and efficiency it is) and fulfill the driving factor of all company's to increase profits.That is all, it is that simple. Every manufacture at one point and time has done exactly the same thing and cheated on emission regs , just in today's online world every one know about it and it is not just a a single news story on the evening news or local news paper or a magazine article in a few specialty magazines. If regulations either emission Fuel economy or what ever become draconian or unachievable company's and people a like will cheat to meet them. That is why it is important to make sure these sorts of regulations are achievable and obtainable. No one wins if they are not. VW could have easily met these emission targets they just chose not to. This is not what happened 1970's where the regulations out stripped the available technology you need to be aware of this all manufactures struggled to meet them, this struggle assisted in giving the Japanese a foothold in NA. But it does prove that when regulations start impacting the viability of what is perceived as necessary products, no good will come from it. It will not benefit the consumer as the product goes to hell, the company stalls and fails to advance technology VW now has 5 years fo catching up to do in emission tech not much a hurdle but it is still there ( it's not as great as the Japanese had to over come in the early 80's due to a decade of cheating their way though emissions) or the environment where all this crap from cheating non compliant vehicles gets dumped, In the end no one benefits.

-

And that was the base engine you had the option of up grading. 142 and 195 HP were the respective top engine option in Ford full size family sedans of the era. Additionally the trucks were equipped 3.55 to 4.11 Not 2.73 to 3.00 geared rear ends, Additionally .the 300 6cyl sported much better torque figures over a wider range. So ya sort of a fail on that point.

-

Listen Riched it is common knowledge in the industry. And it was a quick example that it is common knowledge, not my fault you are not aware of this. There are not too many EU manufactures that design mid-sized diesel engines for third party customers I'm pretty sure you can figure it out. They now will admit nothing about having any involvement in the VT365 program it is one of those programs they want no association with and have bleached it from their walls and their inter-web Really if you were responsible for designing the 6.0L would you admit to it given it's reputation? And really if you have ever seen a 6.0L in the flesh it is plainly evident it is of European origin and design. It is sort of like me telling you to prove it was not. You will quickly find there Zero information on the web about the development of the VT365. Pretty strange how much it touted as a revolutionary engine and won awards initially for it's power and efficiency and perceived reliability. It is a good engine with a near indestructible bottom end capable of crap loads of power. The tighter emissions of pick up use nuked what could have been an engine to rival and likely surpass the 7.3 PS if it had just been designed for the emissions in Pick up use. Quit being obtuse and stay on topic and quit trying to deflect. And none of this changes the fact the 6.0L has basically no issues in it's intended application.

-

It is common knowledge. Do a search. And search to see if IH sued any one over the fiasco. Actual scanned corporate documents no and really it would illegal and irresponsible to post them. But here https://www.youtube.com/watch?v=jJL9EVbVwck

-

Ok first off Honda Datsun (nissian) did not make compliant vehicles they made vehicles that cheated the emission regs by being compliant for a short period of time. NO one in the 70's met the emission regs properly with out either cheating losing efficacy, reliability and or power. So get of this kick the Japanese did what the Americans did not the Japanese just cheated much like Volkswagen has done. The 6.0L was perfect storm of screw ups. The engine for the application as designed has had no major issues. The 6.0L was designed as a school bus engine not as an engine to power pick up trucks. International did not design the 6.0L it was farmed out to a European firm and IH told them they needed a new emission complaint Diesel engine to power school buses it was not disclosed to the designing firm that it was also going to be powering NA pick up trucks. When the designers found out it was going in to NA pick up trucks (after the engine was completed) they were like, Whoa this engine was not designed for that application, and we can not be held responsible for any issues arsing from it's use in that application. In fact they had IH sign off on it that IH would accept full responsibly and they could not held liable for any design issues related to it use in Pick up trucks, that is why IH never sued them for designing a substandard engine, cause it was not. IH ate it all as they had accepted full responsibility knowing full well they were supplying an engine to Ford not designed for or intended for use in Pick up trucks. The fault of the unreliable 6.0L in the F Series lies solely with IH executives and mangers, not the designers, not Ford, not Internationals engineering teams, not the emission regs, but 100% with Internationals executives and managers. In School bus applications the 6.0L has proven to be a reliable and efficient emission compliant engine, it has not suffered failed head gaskets, blown EGR coolers, oil cooler failures, HPOP failures, Sticking injectors, ICP and IPR failures these issues that plagued the 6.0L in the F Series were and are rare problems in School buses with 6.0L engines. The ULSD Cummings from the get go was designed for use in Pick up trucks and was able to meet the demands placed on it in that application with out issue. The 6.0L was not a crappy designed emissions engine, but an engine put in an application it was not designed for. It the perfect example of the results of not fully disclosing the intended use of piece of machinery to the design engineering team.

-

Sorry Richard it was not cop out and the imports had an even harder time meeting the emission regs of the era with cancelled models, delayed launches, sales suspensions, Datsun (Nissan) Honda Toyota and VW all had one time or another sale suspensions from 1974 to 79 until their emission calibrations could be revised or emission equipment modified to meet the regs. Furthermore it was found that after 25k miles almost none were compliant and emitted 2 to 3 times more emissions than equivalent NA vehicles of the same mileage, that issue continued well in to the 1980's. The imports got around it by designing systems that were compliant for a short period time that either failed or wore out quickly then exceeded the allowable emissions, allowing the vehicles to operate in a more reliable driveable manner. This is in part the reason that NY and Cali started yearly emission testing in the early 80's, that testing confirmed that near new vehicles were failing these tests and the imports were far and away the biggest culprits. . It was shortly after wards that the Fed's mandated the 50,000 Mile emissions warranty in an effort to stop this cheating. In was in that era the Japanese took a back seat to the NA manufacturers and were lagging in terms of HP Fuel economy and reliability. As the Japanese had been cheating their way past the regs for a decade and it caught up with them as they had not been advancing the tech lock step with the domestics. It took them about half a decade to close the gap with the domestics and it was not until the early 90's when they were once again on equal footing. Really you are starting to grasp at straws here. The big 3 were not incompetent by any stretch, the regulations were cranked down way to fast far out stripping the tech to do so in a reliable efficient manner. It would sort be like the Govt saying to you today you personally have to be carbon neutral by Jan 1 2017. Can it be done sure it could, would it be able to be done in a reliable and efficient manner ? Of course not as the tech is not yet available for you to do it in an efficient reliable manner. You seem to think that any regulation is ok and if the manufacturers can not do it, it is their fault for not being immediately able to pull the effective reliable tech out of their out their ass and put it in to production. And yes the vehicles were under powered to do the jobs they had already been doing. The only thing that saved them was the 55MPH fed mandated speed limit. When you are having to increase displacements by 25% 50% to do the same work as previously or just not even able to the same job with out modifying them by removing emission equipment they are under powered for the task at hand. You are looking at this through 21st century glasses. Any tech that was developed was done by men in white shirts with slide rules and computers that had less power than a modern calculator. What one man can do on a Computer in a day today would have taken a room full engineers designers and draftsmen weeks to do 40 years ago. You can not apply today's standards, opinions or knowledge to events that occurred 40 years ago and this it what you are doing and then trying to justify it. This not was an era of where every one had a pick up truck to tow or haul or go on vacation with. These things were done with family sedan and believe me a 4800lbs car with 142-195hp towing a 5000lbs holiday trailer could not be driven in a normal fashion let alone a safe one even with a 55MPH speed limit. When ten years previous the same could be done with a vehicle sporting nearly 300 Net HP But that is was was expected and happened due to the emission regulations and not having the available tech to do it in a efficient manner. Bottom line the regs out stripped the available tech to allow to be implemented in a reliable efficient and effective manner. We ended up with vehicles that never actually complied or did not remain complaint, with shortened life spans were unreliable, inefficient, under-powered and just generally marginal for the task at hand and in some cases not at all.

-

Ok lets look at this the curb weight of the 1980 Fairmont ranged from 2750lbs for the 2dr 2800lbs for the 4dr 2900lbs for the wagon. The current fusion weighs 3427 Lbs with the base 2.5L engine.. The Fairmont's base engine in 1980 output was 88hp or 63hp per ton (4dr) The current Fusion base engine output is 175hp or 102hp per ton. Lets step this up a bit the top engine in the Fairmont in 1980 was putting out 119hp or 85 hp per ton. (4dr) In the Fusion it is putting out 231HP or 137hp per ton. . And the spread is actually larger as current Fusion is using the new lower calculation HP figures and not the old SAE Net like the Fairmont. But we were not discussing cars of the 80's we were talking about cars of the 70's So lets look at the 77 Granada again the equivalent of today's Fusion curb weight was 3231Lbs on the 4 door and HP in the base engine was 81hp or 50hp per ton, half of the base Fusion. Lets really push it and go to the average Ford Family sedan in 76 the LTD 4dr curb weight was 4706 LBS the base engine was a 125HP 302 V8 or 53Hp per ton again about half of the Fusion but in a near 2.5 ton vehicle. Even the top engine was putting out a dismal 195 hp and that was from a 7.6L 460 getting 9 and 12MPG with 83hp per ton 20% less power per ton less than today's base engine'd 2.5L Fusion. Lets roll this back ten years. The base 1967 Galaxie had a weight of 3660lbs with a 130hp engine (sae net) 250 Cid 6 cylinder engine for 71Hp per ton a 30% increase over the base 77 LTD. The base Fusion is no rocket by any means and is adequate on today's roads, but would you consider it a safe car to drive with less than half as much hp, 3 fewer gears and much higher final drive ratio?, most of the Ford cars in the era sported a 2.73 ratio rear end and even as high as 2.55 unless option'd with the tow package and you may have got 3.00 , 3.08's or 3.25's (9" rear end) at best. You may beg to differ on it but the facts and numbers don't lie (providing I did the math right lol )

-

I would have to say emissions in the mid 70's did out strip the tech. And Emissions regulations certainly did interfere with these ordinary vehicles' ability to perform ordinary tasks within the law. Besides the huge power loss. think the 400 Pontiac was bad how about 198HP out the 7.6L 460 in 77 and 78 with corresponding single digit FE numbers even on the hyway in some applications. Reliability took a complete dump, with engine life in being cut in half or even more, driveability issues ,stalling,rough running,over heating,no start, no stop (run on), increased maintenance, shorter component life, for things like carbs,many cars needed yearly carb rebuilds to be able to handle the transition from summer to winter due to the lack of available tech in early the emission carbs and ignition systems.. Then there was the fuel economy loss with it being cut in half and crap load more in certain applications that now needed larger engines to do the same job as prior some vehicles were seeing a loss of up to 10MPG or more doing the same job, emission recalls out the wazoo. 74-79 seen some of the absolute worse vehicles ever in terms of power, reliability ,fuel economy to ever come out of Detroit. Yes they complied with the regulations but even then they did not really. Absolutely everyone cheated on the emission testing of the era with specially prepped vehicles, engines and drive-lines for emission testing cause there was not any hope they could offer a vehicle that had any sort of reliability or driveability and meet the emission regs. They certainly tried and we ended up with things like the boat anchor Motorcraft 4350 carbs that had to be retrofitted with Carter Thermoquad's in some calibrations and the emmsion thermoquad was no gem of a carb either. Failed Ford electronic ignition modules, this was a pandemic issue in the early years until tech caught up to make them reliable, the horrific Cadillac EFI system of 1976, it was so bad GM offered a factory kit to swap in a Carb, the Chrysler lean burn system that was almost as bad as the Caddy EFI in the early models again Chrysler offered a retrofit kit for the early systems. All of these failures were a direct result of trying to meet emissions regulations before reliable proper tech was available to do so. The emission regs of the time far out stripped not only the automotive tech needed but also lubrication tech required for engines to last as long as they had previously. There was not one manufacturer with out exception that did not struggle to meet the emission regs, Many did not, and just cheated their way past them. Every manufacturer in NA with out exception was cited for not meeting emissions in each segment with at least one model in each year from 1975 to 1979. Not only that many vehicles that were not subject to yearly inspections (and many of those that were) were, modified, removed,changed or disabled the emissions components, this was even done by the dealers themselves or the local mechanic to resolve driveability issues. Things like gutted Cats, disabled or removed Smog pumps, disabled or removed egr valves, Re-timed distributors, advancing ignition or cam timing, carb swaps, etc etc, the list goes on and on of items that were removed, modified,changed, swapped out to resolve driveability and poor fuel economy issues from emission regulations that out stripped the available tech. Akirby's view on this is not just ."A nostalgia-tinged view of the emissions era, driven by the endless contemporary complaints of the enthusiast press is an essentially revisionist pose" the performance loss (0-60 times) was just one aspect of it also meant that it took big blocks to do the job that, large displacement small blocks could do before and large displacement small blocks to do what small displacement small blocks could prior, this in turn nuked fuel economy twice over as you had the loss in fuel economy due to emissions but also a loss in fuel economy due to requiring a larger displacement engine to do the same job. Performance is not just about enthusiast driven parameters such as 0-60 and 1/4 mile times. In today's world most vehicles have twice the horse power they actually need, 40 years such was not the case and most vehicles had marginally enough horsepower and by today's standards would be considered dangerously under powered. So ya the regulations far out stripped the available tech of the era and we ended up with a crap load of crappy unreliable vehicles with poor driveability that did not meet the emission regs from factory and were modified afterwards and ended up spewing even more emissions and were not able to perform their assigned tasks in a satisfactory manner or even as well as vehicles built 10 years prior. So ya the regulations did out strip the avalible tech at the time.

-

That would be plausible if all 2.0L TDI in NA were affected but they are not and just the vehicles built in NA thus far have been found to have the software defeat. The stuff built in the EU for the NA market appear to not have the software defeat for emission testing. So at this point it looks like just 2.0L TDI's vehicles built in NA are affected.

-

It looks like the 2.0L TDI Audi A3 is not part of the recall and has been cleared . It appears that the affected vehicles are the 2009 through 2015 Jetta, the 2010 through 2015 Golf, the 2013 through 2015 Beetle, the 2012 through 2015 Passat, and the 2009 through 2015 Golf Wagon with the 2.0L TDI all built in NA.It seems vehicles built elsewhere are not affected. So maybe VW NA was pulling a fast one with out Wolfsburg knowing, pretty ballsy if they did but I doubt that Wolfsburg was not in the loop. What will be telling is what kind of package Michael Horn (CEO Volkswagen North America) receives if he is turfed over this.

-

Volkswagen finally got pinched. It is not news that they have been cheating, most all the VW tuners know Volkswagen has been cheating with this for years. But that they finally got caught. What VW did was increase the EGR output when the OBD was plugged in therefore reducing the NOX output. When off testing the EGR output was lowered. This is quickly verified by tail pipe testing with the OBD hooked up and then when it is not. Naturally reducing the EGR flow is going to give you jump in F/E and power. They did not cheat on the emissions equipment but cheated on the programming. The fall out form this is going be huge for VW. VW is not the first to have cheated on emission testing and likely wont be the last. Just about everybody Ford GM AMC Chryco Honda Yota etc etc got nicked at some point and time, mostly in the 70's. Just now the legislation really has some teeth to it and it is not just slap on the wrist like it used to be. Most were nailed cause they had "specially prepped" vehicles for EPA testing. After that fiasco the EPA started to pull random production vehicles to verify what was originally supplied by the manufacturer. I imagine we are going to see a bunch of legal wrangling here similar to what Cat did when they got busted. I can see VW claiming it was an accidently missed line of code that was not deleted after power train development. That will likly be their claim to try to mitigate the "intentional" aspect of it. Unfortunately it will be on the EPA to prove it was intentional and not just an error. They will have to look at the programming in EU spec ECU's to see if their is a similar "anomaly". I know and we all know VW has been cheating but the tough bit will to prove it was intentional, and with the U.S legal system this is not going to happen any time soon. Why did VW cheat, It is not some big conspiracy it was simply to reduce deposits in the intake, the better power and F/E was just a bonus from it. Intake coking is something EGR VW diesels have always suffered from. Lots of back yard how to videos on You Tube for cleaning earlier VW diesel intakes, Lowering the EGR cycle reduced the rate at which deposits form but it also drastically increases NOX. The reduction in carbon deposits would mitigate warranty issues, drivability issues, and reliability issues (not sure how it can get much worse it is VW) And really this was a stupid ass thing to do since the real fix would have cost them about $20 (if that) a vehicle and that is to pull the EGR feed post DPF once all the soot has been dealt with just like other manufactures are now doing. Intake and intake valve coking (carbon deposits) are going to be an issue for many manufactures. DI gasoline engines have this issue. And it is cropping up in the Eco Boost line of engines. The fix is simple for DI gasoline engines and has been in use by various manufactures for about a decade now, Ford neglected to add it to the Eco Boost line, as it is not a cheap fix but it solves the issues of intake valve coking once and for all. It requires the addition of a small secondary port mounted fuel injectors that wash the back of the intake valve and stop the carbon build up. Several manufactures are doing this on their DI gasoline engines. Every one knows this intake valve deposits are an issue with direct injection gas engines and has so for over a decade now. I'm disappointed Ford did nothing to mitigate this issue in the Eco Boost engines and then claimed ignorance when the associated drivability problems that arise from it cropped up. Part of the reason I think the Ford power train engineers as of late are muppets as they are either negligent or stupid, to not address this most basic inherent gasoline DI issue in any manner at all with either auxiliary injectors or an intake service interval. Regardless VW deserves to have their ass handed to them. And really not so much for cheating as everyone has done it (and some still are, VW won't be the last ones busted) , but for being so fricken stupid in the first place. Matthew

-

Uh Mercedes is going back first. And really that is the best you could come up with? An article that an article that is 18 moths old. Because PSA experienced financial issues that some how negates their choice of exploring I6's Especially when they are NOT the only ones going down this road, Come on Richard this is straw grasp even for you. And really it is just common sense. No citation is needed here. I know the mechanical end of things is not your strong suit. So lets simplyfiy it. So lets compare the 2.7 Eco and the BMW 3.0L Inline 6 Simplified casting (Mold cores are much simpler for Inline engines) Easier block surface machining only needs to be done on 2 planes X and Y axis. One less turbo ( that's a couple hundred bucks right there) One less cylinder head. 2 less camshafts. 3 less cam gears One less timing chain One less head gasket. Only one cyl head to machine One less engine deck to machine. less turbo plumbing 2 fewer cats. One less valve cover and gasket. Motor mounts do need complicated construction to abate uneven firing NVH assessory mounting greatly simplified Easier to work on (reduces warranty related Labour costs) 2 fewer Idler pullies. etc...... I can go on and on but you get the point. And really Ford ICE engineers are not exactly the most progressive bunch by any stretch so that is sort like touting the intelligence merits of the special Ed class. So not exactly a glowing resume on that front. Ford is lagging badly in ICE development, when was the last time they had something cutting edge or for that matter new. They are not the only ones but they certainly are not who you would go to for cutting edge ICE tech. So really to say they looked at all sixes and came up a V6 is not surprising nor anything less should be expected from that bunch. Ford I hate to say has not been first to market first with ICE tech for decades all they do now is follow the pack... eventually, when they get around to it. Matthew

-

As for VW that are looking to it as they are sharing some engineering with a supplier Bentley does not use the 4.0L V8 but uses the ancient 6.75 Liter V8 and the VW W12. PSA has the full size PF3 platform which needs a new 6cyl power plant and an 3.0L I6 is being considered to replace the current boat anchor V6 for future model it may find it's way in to some other AWD applications also. PSA is still thinking about re-launch back in to NA Possibly Canada first, (Quebec specifically) and their meager crop of 4 bangers wont cut it in most this market but would be passible in Quebec. Alfa is Alfa always has been, beautiful cars with zero reliability any one that has owned one will know what I mean, FCA has several all new vehicles planned for Alfa over the next few years. As crappy as Alfa is on the reliability front they are far far better then they used to be as they are getting better with every passing year. Also don't forget Fiat farms out a large portion of their engine development. Matthew

-

Well Richard by that logic every one but GM invested $0 dollars in dual circuit brake systems, every one except Chyco spent $0 on computerized auto anti lock braking systems. So what's your point ? And sorry to burst your bubble but Mercedes BMW, Fiat ,PSA Peugeot Citroen, VW (for Audi/ Bentley) Jaguar/Landrover/Tata and of course Volvo are looking at Inline 6's or are developing their next generations of I6's. So not any where near cut and dried as you like to make it out to be. Sorry say Richard but you are behind the curve on this one, the I6 offers several advantages to manufacturers over the V6 to achieve the same equivalence or better than a V6 in a given chassis. In short you can get an engine with better NVH, more low end torque, higher efficacy ,with fewer parts in engine and exhaust for less overall cost than a V6. That is why we are starting to see a resurgence in the interest in I6's within several of the auto manufacturing groups. Not just Jag and Mercedes Currently the V6 offers no technical or cost advantage over an I6 the only advantage is packaging and that is becoming a non issue as 6's are more and more just found in large mid and full size platforms. Here is an R&T article from earlier in the year that sort of touches on it. http://www.roadandtrack.com/new-cars/videos/a8645/the-enginerdy-dept-straight-six-revival/ So regardless of your personal feelings on the matter I6's are once again on the radar for a variety of reasons most significantly lower over all cost. And in the auto industry cost takes precedent over nearly everything. Matthew

-

For some applications yes they are too long but now with only larger vehicles utilizing a 6 cylinders the switch to housing a longitudinally mounted I6 would be pretty straight forward. Gone are the days of Tempo and Citation sized vehicles housing 6 cylinder engines. With the HP out put of modern 4 cyl engines the 6 pots will be bumped from all but the larger vehicles who are now mostly sporting AWD either standard or optional. We are talking Fusion size and above here. The current Fusion could easily house a 3.0L Inline 6 under hood and drive only the front wheels or AWD. It can be done wit out lot of fuss with the tech available today, 20 years ago such was not the case. Mercedes is not looking at this cause it is going to cost more than the current V6's they use, there is obviously cost savings and product improvement associated with it. Matthew