iamweasel

Member-

Posts

223 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Downloads

Store

Everything posted by iamweasel

-

All of the above, honestly. Just seems like every high level decision lately isn't working out. But more importantly from the dealer side, the one thing that is much worse than before is the simple lack of communication regarding what's going on with production, scheduling, parts availability, product support, etc. All the basics of building cars and trucks. Ford seems to almost go out of their way to NOT help answer questions and find solutions to problems. The randomization of which orders get scheduled or cancelled and which ones get priority is a total cluster%$#@. My company has several OEM's and the only company we hate dealing with more than Ford is Hino.

-

I know a lot of Ford employees, some very high up, and I also know several Ford dealers (including my own company.) Not one person I know has anything good to say about Farley and the crew of execs running the company at the moment. The cumulative impact of 2 bad Leadership groups in a row (CEO's/Top Managers) is really starting to take a toll......

-

New Light & Medium Duty News

iamweasel replied to Joe771476's topic in Ford Motor Company Discussion Forum

GVWR doesn't have anything to do with it. At least in Class 3 and above, which is what I'm familiar with, there are no exemptions based on GVWR. It's basically whether or not your engine meets the new requirements in California and the Isuzu diesel and Cummins L9 don't make the cut. Engines like the Detroit DD5/DD8 and Cummins B6.7 passed the test. Also note there are still "CARB" certified trucks that are not allowed to be sold in California. At least with the way I am ordering our trucks, I have to choose between these 3 options: No CARB certification (To be registered in the other 45-49 states depending on which way the wind blows. For some states, like PA, you can't register a truck there if you do this.) CARB certified / to be registered in the other 49 states (Adds ~ $1,500 to the truck price. You need this option to get the Clean Idle Sticker. You can safely register these in all 49 states.) CARB certified / To be registered in California (Adds $12K more to the price than option #1. In addition, with DTNA they are only going to build so many of these engines this year so only dealers in California have allocation for this and it's in limited quantities.) -

New Light & Medium Duty News

iamweasel replied to Joe771476's topic in Ford Motor Company Discussion Forum

Who knows.....there are so many new rules in the process of implementation everyone is just confused across the board. CARB alone is bad enough then you add EPA, OmniBus, ACF into the mix it just makes it chaos. I'm just glad I'm not in California like you are. I feel for people who do what I do out there. It's a nightmare.... -

New Light & Medium Duty News

iamweasel replied to Joe771476's topic in Ford Motor Company Discussion Forum

On the Daimler side, they tell us that it's the date of the engine is what matters. You can't build an engine in Detroit on 1/1 and ship it to North Carolina to be installed in a truck that same day, you know? (DTNA also flipped to 25MY starting 1/1/24.) So over the past 3 months theoretically you could have: 1) A 24MY truck with a 23CY engine 2) A 25MY truck with a 23CY engine (engine built a week or two before the year is over) 3) A 25MY truck with a 24CY engine DTNA really goes out of their way to avoid #2. They don't want to have any gray-area issues with the EPA/CARB, so they will start to produce their 25CY emission engines late in 24CY and time-it so any truck rolling down the line in 24CY gets a 24CY engine. I have had a few oddball trucks over the years like item #2, though. Those situations only happened when there was a production/supply issue of some sort that messed up the timing. -

New Light & Medium Duty News

iamweasel replied to Joe771476's topic in Ford Motor Company Discussion Forum

PACCAR has been particularly aggressive of late in the states I deal with. Their orders have dropped dramatically so they have a lot of build slots to sell and when that happens they will undercut everyone on price if they have to. PACCAR has always had the most volitile pricing. They claim to be some premium brand but they will get into the mud on pricing when they need to. Mack/Volvo, International and Ford may have slower order intake, too, but seems they have been struggling to get trucks built big-time and haven't reached the point where they've "caught up" to their pent up demand. Given that, they have been steady on the prices lately. With my FTL/WST business, on the FTL side we are still working through our backlogs, too, and I expect very limited availability for the next 12 months. Almost all our 24CY slots are spoken for already. On the Western Star side, we have far more availability - especially given they are increasing WST production by 30% in 24CY - but we are still pre-selling most of our slots so we have held our pricing steady. Sure we have lost some deals to PACCAR as they have gotten more aggressive, but we don't need to chase that right now. On class 8 dumps, over the past 2 years PACCAR was selling them for $280-300K around here and we were at $230-240K. In normal times, we would be around the same price as PACCAR so that just shows you how much they jacked their margins on everyone. For 24CY, they are now quoting those same trucks for $240-250K which is right where we are. On Class 6-7, they have been $3-5K under us lately.....and Ford is usually $5K below us. -

New Light & Medium Duty News

iamweasel replied to Joe771476's topic in Ford Motor Company Discussion Forum

I may have misunderstood what you were saying a bit, and if so, my bad.....and NO I do not consider those Chevy/International trucks premium in any way. -

New Light & Medium Duty News

iamweasel replied to Joe771476's topic in Ford Motor Company Discussion Forum

I don't think there would be enough of a market for "premium" trucks in Class 3-5. Those are very price sensitive segments and don't see a lot of buyers paying extra money for the GMC when they can get the Chevy. Even in class 6-7, there are some (PERCEIVED) premium products there (Paccar) but they don't carry nearly the market share as PACCAR's class 8 trucks do. Part of that is due to less demand for premium trucks in that segment and the other, quite frankly, is because there is nothing whatsoever that is premium about those medium duty PACCAR trucks. They are as cheap and plasticky as anything else in the segment and with their small cabs there really isn't anything special about them. (PACCAR can also undercut many of the other Class 6-7 brands on pricing, too, when they want to.) -

New Light & Medium Duty News

iamweasel replied to Joe771476's topic in Ford Motor Company Discussion Forum

Think I saw one the other day, too, and I believe it was a gas motor..... -

New Light & Medium Duty News

iamweasel replied to Joe771476's topic in Ford Motor Company Discussion Forum

Right.....no other state has the same rules as California right now. Oregon was following that path but then bailed out of some of the rules a few weeks ago. So as of now, at least the way we are ordering trucks, the groupings on the Daimler side are: 1) California - on its own island of rules (BIG Cost.....$10-15K added cost we have to pay the OEM for Cali registered trucks) 2) Oregon, Maine and Pennsylvania - must order a specific CARB certification for those states, but it only adds $2K cost to the trucks. With this certification, though, if the customer buys an extended powertrain warranty the cost of that warranty is lower than non-CARB certification so you can actually lower that $2K CARB penalty to $300-$500. 3) Everyone else, where you can do non-California CARB or non-CARB certification similar to option #2, and in most cases we are still doing the $2K CARB certification because you have to do that to get the clean idle sticker and the net cost increase is minimal when doing an extended powertrain warranty (which many customers do) -

New Light & Medium Duty News

iamweasel replied to Joe771476's topic in Ford Motor Company Discussion Forum

The issue with the California regs is there are multiple regs in that same state, and they each bring different rules to the table making it extremely complicated and almost impossible to understand/coordinate. There are CARB rules, Omnibus low NoX rules, Advance Clean Fleet (ACF) rules, Advance Clean Trucks (ACT) rules, Clean Truck Check reporting, etc. With truck orders for next year, we can bascially pick 3 certification levels on each truck: 1) No CARB certification 2) 49-state CARB 3) California CARB Due to OEM's needing to meet both California regulations and nationwide EPA requirements, on the Daimler side, they basically have given the dealers 2 groups of slots to order for 24CY: A bucket of slots where you can do #1 or #2, and then another bucket of slots to get #3. (Those trucks with #3 will cost $10-15K more than the trucks with the #2 certification.) On top of that, there were new rules issued that changed what trucks can/can't be run through California. For instance, we sell to a large body builder in California and now they are saying any truck that gets upfitted there, even if it will be registered in another state, will need the #3 certification. That will absolutely destroy the competitiveness of that body builder versus their competitors in other states. They might as well pack up and move their business to Arizona or Nevada. So that being said, for the group of slots my company has to build #1 and #2 certifications, we are looking to transfer those slots to our Arizona stores and have the trucks invoiced out of those stores to bypass all this crap in California. It's an absolute $%#@ show.... -

UAW Demands 46% Pay Hike

iamweasel replied to ice-capades's topic in Ford Motor Company Discussion Forum

As one of the special Heritage products, the Mustang gets a bit special treatment when it comes to analyzing vehicle profitability. It isn't held to the same standards as other vehicles. A single shift plant is a killer for the vehicle line P&L because the fixed costs of running that plant are allocated against fewer units, but not much they can do about it right now since 2 shifts worth of Mustangs would be far more than market demand. (And they don't produce anything else at Flat Rock to share the cost burden.) -

UAW Demands 46% Pay Hike

iamweasel replied to ice-capades's topic in Ford Motor Company Discussion Forum

Well Bo did lose 70% of his big (bowl) games so Hackett did bring Bo's losing ways with him to Ford. -

UAW Demands 46% Pay Hike

iamweasel replied to ice-capades's topic in Ford Motor Company Discussion Forum

Well that's sad to hear. One of my best friends was fairly high up in Manufacuring at Ford until a few years ago - he was always the one with the inside scoops at all the plants. (He was on a long-term personal mission to get Chicago closed and he says it's his biggest career regret that place is still running....LOL.) That being said, he, and some others I knew, used to say good things about Flat Rock outside of the building itself. Maybe things have gone downhill in the past few years. -

UAW Demands 46% Pay Hike

iamweasel replied to ice-capades's topic in Ford Motor Company Discussion Forum

That plant design stinks. It's small and chopped-up inside. It's always been a good running plant with good people, too, and Ford has had so many ideas for what to do there but.... ...then the Ops folks go "oh, you can't do this there" and "you can't do that there" so it just seems to have no grand plans for it. I was told years ago if it wasn't for environmental concerns (and cost I'm sure) they'd tear it down and re-build a plant the right way on the same land. -

UAW Demands 46% Pay Hike

iamweasel replied to ice-capades's topic in Ford Motor Company Discussion Forum

Good. If you're going to pay premium wages then you better get premium performance. When I was a line supervisor, I had one lady who was buddies with the nurse in the medical office. She was constantly asking to goto the bathroom or said he had a headache, etc. Every time she got a break she would just go into the medical office and chit chat. My floater, who was supposed to cover 20-25 stations, was seemingly on her station all the time due to her taking so many breaks. After trying to reason with the lady it was clear she was just someone who didn't give a crap as long as she got paid. (To not get in trouble the medical nurse would issue her tylenol or some other BS "prescription" and after going through her records she had something like 300 prescriptions in the last 100 days. LOL....) So I spent a weekend reading through the "rules" and then on that Thursday (I was doing C-Crew at the time) I got the page from her station 15 minutes into the shift. I'm mumbling to myself "what now" and walked up to her station and of course she wants to use the bathroom. I look her right in the eyes, say okay, click a button on my watch, walk away and note the request time in my pocket notebook. (Prior to that, I'd normally page the floater right then and ask him to come over but this time I didn't do that and she noticed.) 10mins later she pages me again. I walk over and she starts yelling at me that she has to goto the bathroom. I say okay again and walk away. 10mins later same thing....but this time she starts yelling at me as I'm walking away but I ignore it. Then after one more page I finally get the floater over to her station around 44 minutes after she asks to use the bathroom. and note that in my Every time she needed a break I'd do the same thing. Fast forward a week later and I get called into the Assistant Plant Manager's office and the UAW committeeman is there. She filed a formal complaint against me and I was charged with not letting her have required breaks, etc. The committeeman was a loudmouth and after ranting for a while I simply said "per rule # XXX we must offer relief within 45 minutes of the request", whip out my notebook, and show them both the notebook with the request times and what time the floater got there - all within 45 minutes of each other. The committeeman was speechless. LOL..... Good times....but even after me that lady kept working the system to get paid as much as she could and work as little as she could. Those are the types of line workers where rules are needed to get rid of them faster. (Note 98% of the line workers were great. There was just a small group of people that were like that.) -

Part of the issue with the Edge is that it was built in Oakville, which has always been at the top of the list for the "what plant do we close next" crowd inside Ford. Between labor issues, exchange rate complications and land/facility issues at that plant I'm surprised it's still going, honestly. All the "do we close it or not" proposals running through the company over the years tends to scare away the strategy planners from allocating funds to those models for refreshes/new launches. That's part of the reason it didn't get a lot of changes over the years.

-

UAW Demands 46% Pay Hike

iamweasel replied to ice-capades's topic in Ford Motor Company Discussion Forum

You are 100% correct that line workers and the plant's themselves get too much blame on quality. A high majority of vehicle issues are NOT due to plant assembly. (Spent 3 years of my Ford life digging through JD Power and Consumer Reports surveys, warranty claim data, etc, so trust me.....I know. I also spent a year in an Assembly Plant - Michigan Truck - and also got involved in a lot of that.) That being said, the flip side is that means the line workers are far from the company's most valuable asset. (And yes, I have worked line jobs, too, so I know EXACTLY what it's like to do those jobs all day.) Those job's for the most part can be done by any average joe in any state/country. So many of the jobs are "poka yoke'd" (to borrow one of my grad school buzz words LOL) and just about anyone can do the jobs. (Look up the word if you want, I could use another word for what I wanted to say but it was not very polite.) Bottom line is Ford would shut down every plant tomorrow and move to the south and/or Mexico if didn't cost a zillion dollars to build a whole new plant network. (Well truthfully Ford may not really do that as I said previously the Ford family is far too nice for that, but I'd bet GM and Stellantis would have no issue leaving the midwest behind if they could.) It is not hard to find people to do those jobs. Just look at all the new plants in the south - none of them have a hard time getting workers because most of the positions do not require any special skills so the available labor pool is huge. I do not say this to be disrespectful as I still work in the industry and respect how hard everyone works. I'm just being honest in my opinion. Good engineers, designers, operations folks, etc are the ones who ultimately decide whether a given vehicle is a success or not, and those positions are much harder for the auto companies to fill. -

So your source for why Hackett is good is an advertisement from a consulting company he hired? LOL...yeah, I mean that's great proof. Even so, I even took the time to read that linked article and I must say it was an impressive amount of buzzwords that collectively said nothing. I particularly like this quote: "Having cross-functional teams from engineering, design, purchasing and more, has been a breakthrough, because they gain empathy and respect for each other’s practices and work together, rather than sitting in silos that tend to block each other’s effort." I hate to break this to you but that was not something new at Ford. Every week at Ford for 10+ years (pre-Hackett) I sat in numerous cross functional meetings to do exactly what that article states. This article, from an independent source, is a more accurate portrayal of Hackett at Ford: https://www.forbes.com/sites/georgebradt/2020/08/04/what-you-must-learn-from-jim-hacketts-failure-as-fords-ceo/?sh=331058c843b8 (NOTE: I am not commenting on Hackett as a person or his business dealings at any other company. I have no working knowledge of whether he was any good or not at the other places. I do know, though, that he was a miserable failure at Ford.)

-

"a direct result of Jim Hackett's design thinking taking root at Ford Motor Company." Seriously? You give this guy WAY too much credit. First of all, the CEO has literally ZERO impact on interior design. I've been in countless product design meetings in my life and CEO's just do not get into that level of detail. Secondly, Hackett was actually anti-Maverick and Bronco Sport from the beginning. Those products were done with his reluctant support - he was not a fan of entry level segments. (Slimmer margins - he wanted the R&D spent elsewhere but .) Jim Baumbick was really the driving force behind the Maverick. From what I'm told, Baumbick and Hackett were quite at odds with it. Hackett wanted costs taken out of the program in order for it to proceed and Baumbick basically had to tell him he needed to be empowered to make decisions without management interference to get things done as quick as Hackett wanted. This led to Hackett never being involved....no decision on that program went any further than Hau Thai-Tang. Sorry for the Hackett rant but that guy was not qualified to run an automotive company and everyone I know at Ford was glad when he left. (Including one of his direct reports who I am very close with.)

-

UAW Demands 46% Pay Hike

iamweasel replied to ice-capades's topic in Ford Motor Company Discussion Forum

LOL.....can't spell unwarranted without a U, A & W. -

UAW Demands 46% Pay Hike

iamweasel replied to ice-capades's topic in Ford Motor Company Discussion Forum

Seats were one of those components that Ford used to buy as complete units from suppliers but my F-150 program was the first to launch the new F-Family seats where we started to do more of them in-house. (We would buy the frame in small , medium or large from the seat supplier then do the rest of it in-house.) But that was 15 years ago and don't really know if they truly rolled that out to all the other models or just gave up and started buying complete seats again. As far as Chicago is concerned, that would probably be one of the plants that needed to do more of that kind of thing given the plant was old and small. That plant was considered our worst assembly plant for a number of reasons and if there were to be closures the 3 always on the top of the list were Chicago, Flat Rock and Oakville. (Again, that hit list may look different now....not trying to freak anyone out. LOL...) -

UAW Demands 46% Pay Hike

iamweasel replied to ice-capades's topic in Ford Motor Company Discussion Forum

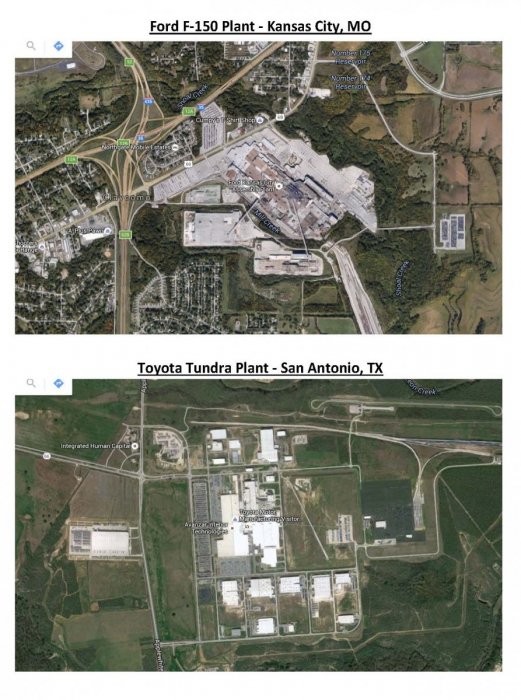

GM and Ford has done that a little bit here and there but mainly out of necessity due to the plants they have not being able to do certain things. I'm not as familiar with Stellantis. On the Ford and GM side, my understanding is their total 3rd Party labor pool is estimated to be a small fraction (say no more than 10%) of what the transplants use. Attached is an interesting photo. I had to do this on F-150 when we were setting some things up for Dearborn. Note Ford's KC plant how there is just the plant in that area. (The two buildings just south of Mill Creek are Ford's paint and body buildings so everything shown is Ford-owned.) Contrast that to the Tundra plant. Look at how many other buildings there are. Toyota has the big plant in the middle but everything else is a 3rd party subassembler. (~ 20 in total.) Even with their main plant, my recollection was half of that left section was leased-out to subassemblers, too.