-

Posts

2,636 -

Joined

-

Last visited

-

Days Won

15

blksn8k2 last won the day on December 5 2023

blksn8k2 had the most liked content!

Recent Profile Visitors

8,444 profile views

blksn8k2's Achievements

633

Reputation

-

Although it was never my intention, now that it's finished it appears as though I've built my version of a New Edge Eleanor. 😲

-

-

I've also seen youtube videos that claim some of the noise comes from the VCT (Variable Cam Timing) solenoid which is located in the driver side valve cover. Interestingly, on my '23 F-150 Tremor with the 5.0L there is a foam cover on top of that valve cover only (separate from the foam covers on the injectors) and that engine is worlds quieter than the one in my previous '18 F-150. It's also the Gen 4 Coyote vs the Gen 3 and I'm sure there are other more significant differences including cylinder deactivation. When I was looking at '23 F-150s a dealer salesman told me that Ford had issues with noisy 5.0Ls in '18 and '19 F-150s but that was probably just BS in hopes that I would take less for my '18 on a trade.

-

Found a set of used side scoops on eBay. Had to do a little finish work on them but they weren't too bad. They were flat black when I received them. I'll have to do a color wet sanding to get rid a some minor paint issues and then spray one more coat of gloss black before they go on the car.

-

Thanks! Here's a rear quarter view. Next change will be replacing the side scoops with a set from an '03-'04 Cobra and maybe a rear bumper diffuser. Might as well go all out on the aero stuff at this point. Another recent update was replacing the hood prop rod with gas struts from MRT.

-

Finished project. The car also has some Roush body parts including their side skirts and side exhaust, rear bumper skirts and rear deck spoiler. Also have some other progress photos here:

-

The fender brackets finally came today. It's only been 15 days since I ordered them. Today I did what was hopefully the final trial fit before painting.

-

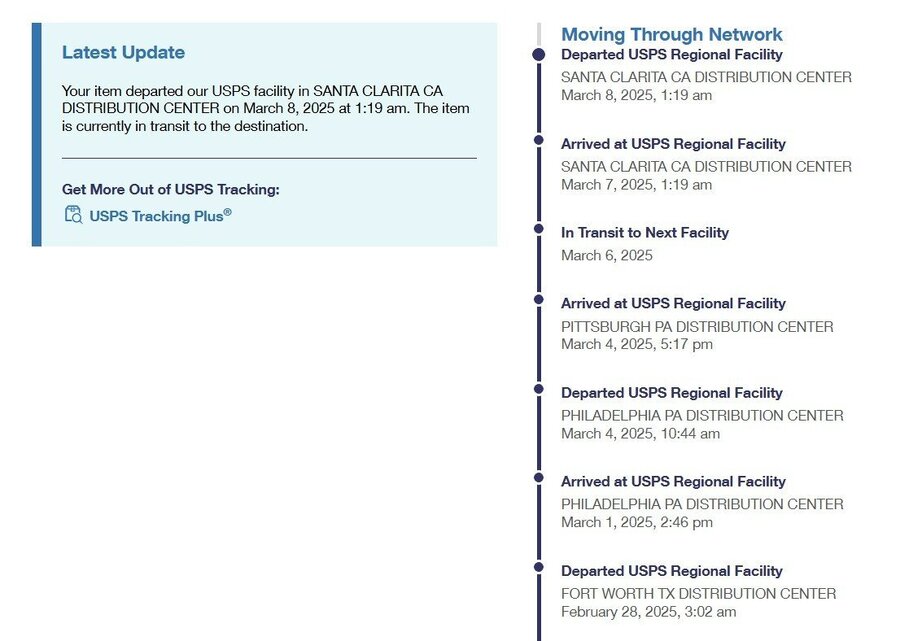

USPS tracking shows the brackets went from New Jersey to Connecticut and they are now back in Pittsburgh exactly one week after they left Pittsburgh the last time. After filling all the scratches, divots, etc. with spot putty and/or body filler and then lots of sanding, I sprayed the first coat of primer today.

-

Checking USPS tracking just now shows that the brackets are now in New Jersey...

-

This has nothing to do with the shipment of the fender brackets but it does involve the shipment of the bumper itself. When I received the bumper it was in a really small box compared to it's installed size. When I told the UPS driver that there was supposed to be a complete bumper in that box he just shook his head in disbelief. When he delivered another package two days later I showed him the actual size of the bumper and he was like there's no way that came out of that little box. The bumper is made out of polyurethane which is a high density synthetic rubber-like material. It took over an hour with a heat gun to get it back into the final shape. Believe me, I had my doubts that would ever happen. The reason the manufacturer (KBD) ships them that way is to avoid having to ship something that large via special truck and the accompanying freight charges. The box it came in is behind it in the first photo. As you can see I also stuffed round metal cans and pieces of wood in the openings so they would hold their shapes as they cooled. Talk about a WOW! moment.😗 This style of bumper is also available in fiberglass but I suspect this one will survive minor bumps and bruises without cracking the way 'glass might. I don't intend to race this car but I could certainly see the advantages of using something like this on a track car. Other than the fender brackets I'm also waiting on the special primer required to paint this stuff. I also added some metal bracing under the larger opening as well as metal braces to attach the bottom of the bumper to the radiator core support/frame crossmember using the same mounting points as the original bumper. And I'm also re-using the original fog lights and their plastic housings.

-

I had our local postmaster verify that the package at least had the correct ship to address since that's not something I could see on the USPS tracking website. She also pulled up an image of the package which showed that it was a bubble wrap envelope. Her guess was that it probably got stuck in a larger mailing sack which then got filled with other mail for the west coast. No change on the tracking site from what I posted yesterday. Regardless of the reason it's pretty hard to defend a package crossing the country at least 2.5 times and it still hasn't reached the destination.

-

My bad. It was actually in Santa Clarita, CA this morning. Not Santa Clara. You can't make this shit up! I thought it was bad enough that they overshot the target by going too far east to Philly and then too far west to Pittsburgh. It'll probably end up in Fairbanks, Alaska or maybe back in Texas before it ever gets here...😡

-

blksn8k2 started following USPS Idiots

-

I decided to replace the front bumper on my '99 Cobra with a reproduction of one from a 2000 Cobra R. I had already installed a Roush body kit on the car several years ago and always wanted to get the front of the car down to the level of the Roush side skirts but I didn't want to use the Roush front bumper cover since it would lose too much of it's Cobra identity, IMO. The Cobra R bumper cover with its lowered splitter solves those problems. Unfortunately, the brackets that attach the ends of the bumper to the front fenders are pop riveted to the inside of the bumper and I didn't want to drill out those rivets on a perfectly good original bumper and they weren't included with the new bumper. Ford also no longer makes those brackets due to the age of the car. However, Late Model Restorations (LMR) does make reproduction brackets. So, I ordered a pair of their brackets back on 2/26/25. LMR is in Waco, TX. According to the USPS tracking number, the package was in Pittsburgh, PA on 3/4/25. Because I live in west central Pennsylvania I assumed the package would have been here by now. Afterall, today is 3/7/25 and it was less than 100 miles away four days ago. Wrong. Can't do that. Guess where it was today? Santa f'n Clara, California! WTF? Musk can't DOGE these a-holes fast enough! Here's a photo of the unpainted Cobra R bumper during trial fitting on the car.

-

My '23 F-150 Tremor has been very reliable with the only manufacturing glitches being a poorly installed wire connector for one of the front bumper sensors and the front door windows having the super annoying "bounce back" issue. Both were fixed under warranty. The window thing is a bit of a mystery to me in that this seems to have been a known issue since well before my truck was built in Jan of '23. There have been multiple TSBs dating back to 2021 stating that the front window control modules (both sides) need to be recalibrated to change the sensitivity settings. My question is if Ford knew about this that long ago why did they continue building new trucks with the wrong calibration? Makes no sense.

-

GTD documentary coming Dec. 10th

blksn8k2 replied to DeluxeStang's topic in Ford Motor Company Discussion Forum

So did Ford ever race at the 'Ring with the GT and if so what kind of lap times did it run?